hyperMILL 2023 offers important improvements in many areas. Following this annual release, customers will receive a product update (previously service packs) every 6 weeks. This agile new software development and issue strategy ensures that your business is always working with the very latest product improvements.

Release Strategy – Now as Fast, Agile & Responsive as our Service

As an OPEN MIND customer, you will be familiar with the exceptional service and support that underpins why hyperMILL is the industry’s leading CAD/CAM solution. To remain a benchmark in the manufacturing industry, OPEN MIND invests significant resources into product research and development. The result is a development team that works tirelessly behind the scenes to continually evolve the technology and provide annual product updates.

From 2023, OPEN MIND will be changing the way you are provided with updates, so you’ll be able to update hyperMILL as soon as the latest updates become available. Starting with hyperMILL 2023, OPEN MIND will release one new software version annually in December. Following this annual release, you will receive a product update (previously service packs) every 6 weeks. This agile new software development and issue strategy ensures that your business is always working with the very latest product improvements. Of course, OPEN MIND will be providing comprehensive information on the new features and updates as they become available.

hyperMILL 2023 Brochure

![]() Download the hyperMILL Version 2023 brochure4.78 MB

Download the hyperMILL Version 2023 brochure4.78 MB

What's new in hyperMill 2023?

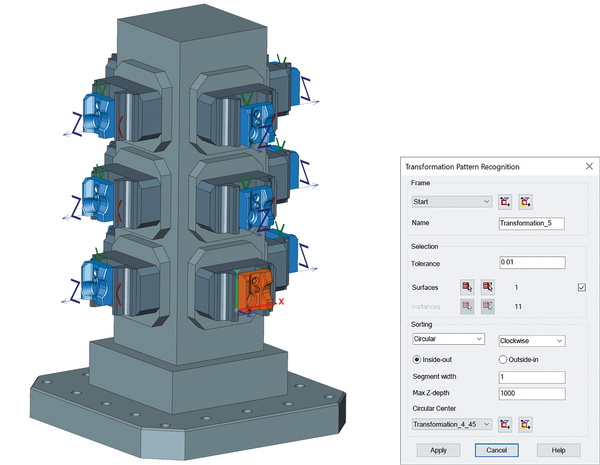

“General transformation pattern” feature

This feature uses a selected reference geometry and searches for the same reference in all other models. From this, it creates a general transformation pattern, including the associated frames. The feature can be used in many ways, for example if there are multiple components.

Benefit: Straightforward creation of general transformation patterns.

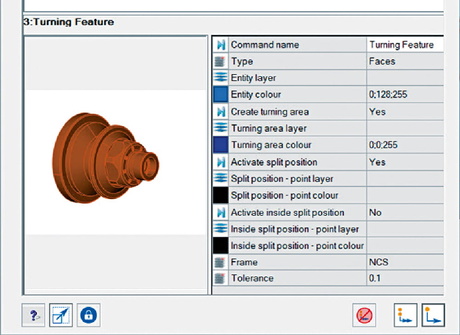

hyperMILL AUTOMATION Center

The hyperMILL AUTOMATION Center offers several new features:

- Recent scripts

Users can quickly select and apply recent scripts from a dropdown menu. - Script filter

Filter can now be used to narrow down existing scripts to make it quicker to find the required script. - Bookmarks

Components and functions can be bookmarked so that you always have quick access to them. - Convert components to subscript

Components can be easily converted to subscripts in the future to improve structuring. - Support for turning features

Turning features are now fully usable in the hyperMILL AUTOMATION Center. - Job report

Job reports are fully usable.

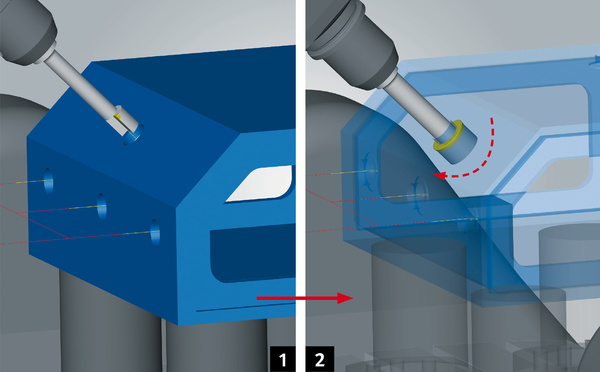

2.5D Back Boring

This new strategy enables back boring tasks to be programmed on machines with different kinematics conveniently and easily. Tool holders and inserts, as well as monobloc tools, are displayed one-to-one in the virtual machine and checked for collisions. This ensures the highest level of safety for this critical type of machining.

Benefit: Simple and reliable programming for back boring.

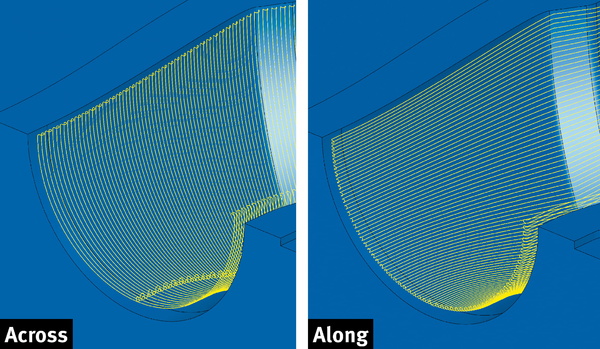

5-axis halfpipe machining

This strategy makes programming high-quality toolpaths for halfpipes and tubes convenient. The user interface is designed to be easy to use and intuitive. The calculation mode of this strategy enables a wide range of applications and ensures the best possible quality of the output toolpaths. Sharp edges, for example, are accurately mapped, and surface quality and precision are thus ensured in these areas as well.

Benefit: Intuitive operation, high quality of tool paths, wide range of applications.

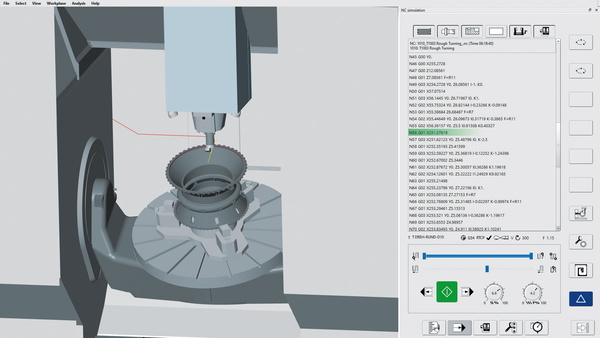

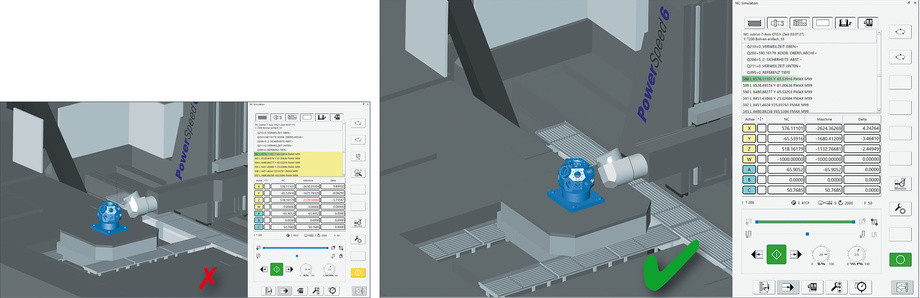

NC Optimizer – Optimization of additional axes

Manually positioning fixed rotary axes and parallel axes is very time consuming. In most cases, the user can only determine a suitable and collision-free solution for the machine kinematics by performing several tests.

Fixed rotary axes and parallel axes can now be optimized with the NC Optimizer, as it automatically finds a kinematically correct and collision-free solution. This also applies to machines with Hirth gearing. As a result, users will no longer lose time by manually interacting with the axes.

Benefit: Simplified programming.

Support for mill-turn machines with Siemens control system

hyperMILL VIRTUAL Machining now supports mill-turn machines with A/C kinematics. This means that both technologies are perfectly combined in one operating environment, and the user benefits from maximum safety and process control.

Benefit: Increased safety, process control, and efficiency.