For surfaces and special tasks

Simple programming for the best surface quality.

hyperMILL 5AXIS provides a wide variety of machining strategies for the broadest possible range of manufacturing tasks. Programming is simple and gets you quickly to your goal while achieving the best possible surface quality.

5axis contouring machining

For milling grooves, scribing, engraving, deburring, and chamfering. With 5axis Contouring, the tool is guided on or to the side of a curve with a fixed orientation to the surface. This strategy allows the user to manually change the tool orientation for an entire area or for a specific area, if necessary.

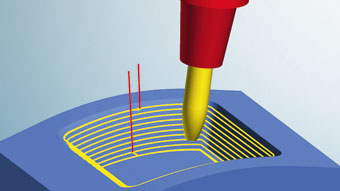

5axis top milling

For machining of large, moderately arched surfaces, top milling reduces cutting time by using greater step-over between adjacent paths. Automatically adapted tool tilt angles ensure high surface quality on concave surfaces. Thanks to multiple infeeds and stock detection, this strategy can also be used for very effective 5axis roughing.

5axis swarf cutting

For machining arched surfaces, swarf cutting machines the workpiece surface with the tool flank. Large step-overs between paths or full-depth cutting reduce milling time and improve the workpiece surface. Multiple axial and lateral infeeds make swarf cutting also suitable for roughing or combined semi-finish and finish operations. Defined stop and milling surfaces, as well as stock tracking, allow precise and simple optimisation of machining operations.

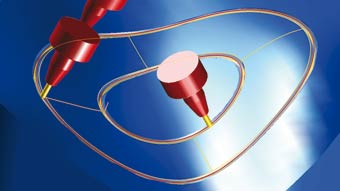

5axis shape offset finishing

Barrel cutter shapes that enable larger infeed are now supported by hyperMILL.

Benefit: Very short machining times and optimised surface quality.

New, spiral movement sequences enable a constant, continuous infeed.

Benefit: Better surface quality.