hyperMILL 2021.1 features numerous innovations and optimizations.

There are several highlights, particularly in the area of mold making. The efficiency and machining quality of 3D Profile Finishing and 3D Z-level Shape Finishing have been further improved. One of the top highlights is the new 5-axis Radial Machining strategy that enables high-quality production of bottle shapes, for example.

The new hyperMILL SIMULATION Center provides improved machine simulation for turning and milling operations. Another highlight is 3-axis Simultaneous High Performance Turning.

![]() Download a hyperMILL Version 2021.1 brochure3.03 MB

Download a hyperMILL Version 2021.1 brochure3.03 MB

What's new in hyperMill 2021.1?

Edit Toolpath

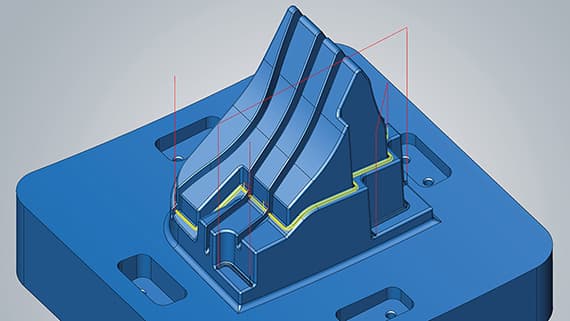

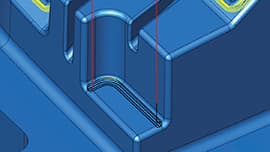

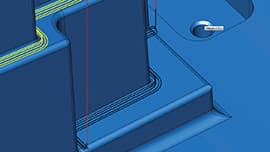

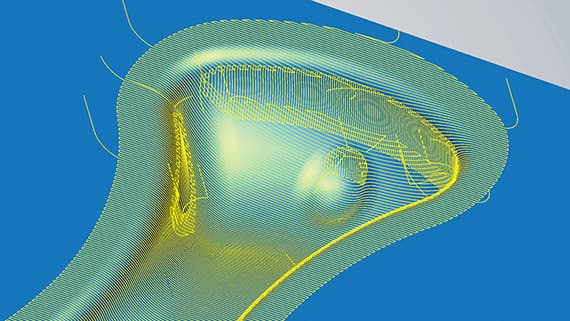

The option to subsequently edit toolpaths after initial tool path generation is particularly important in tool and mold making. The new “Interactive mode” in the Edit Toolpath job allows the user to edit existing toolpaths very flexibly, and so adapt them optimally to the component conditions. The intuitive operation makes it easy to trim the toolpath, for example, at selected points and curves, in a specific area, or on a plane. Complete toolpath sequences between two G0 movements can also be selected and removed.

Removed toolpath areas on the component

Features

- Trim toolpaths

- Delete toolpath sequences

- Intuitive operation

3D Optimized Roughing

This strategy features various enhancements.

Maximum step height for high-performance milling

The “Maximum step height” option allows a continuous allowance to be achieved, even with a large axial infeed. The remaining material on inclined walls is removed from bottom to top after roughing according to the defined step height.

Plunge points

Plunge points can now be defined for machining. This allows the machining operation to be started directly in an existing hole without an additional approach macro.

NC output with G2/G3

The NC output for circular movements can now be controlled in the strategy.* This means that it is now also possible to output these movements as G2 or G3 commands in the NC code. For controllers with limited memory, a smaller NC program can therefore be generated and processed without any problems.

*Note: This option is not available in high-performance mode.

Benefit: Constant stock allowance, more efficient machining, better support of machine controllers with limited memory.

3D Profile Finishing

The “XY Optimization” command has been added to machining with the X or Y axis infeed strategies. If, for example, an area cannot be optimally machined in the X-orientation, it is automatically machined in the Y-orientation in order to maintain a constant infeed. The “Smooth overlap” command ensures that these areas are machined seamlessly.

Benefit: More user-friendly, improved surfaces.

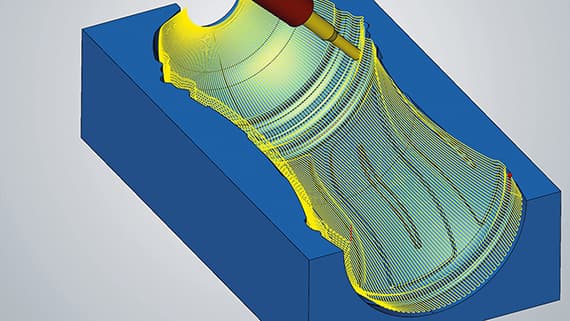

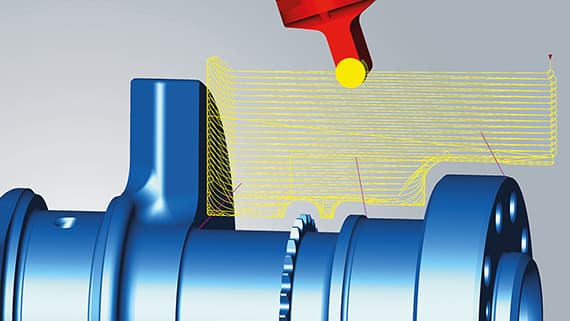

5-axis Radial Machining

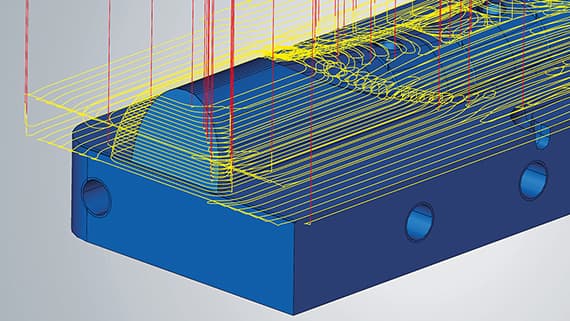

This new strategy allows bottle shapes to be programmed very easily and high-quality surfaces to be generated. Thanks to a new, radial projection method, the toolpaths are calculated very quickly, and the user can use various machining strategies to respond flexibly to the existing component conditions.

This strategy offers “High Precision Surface Mode” and “Smooth overlap” to ensure the best surface quality and clean transitions. These commands are integrated as standard and guarantee high-precision machining.

The 5-axis inclination of the tool is controlled by simple tilt options in the strategy, regardless of whether 3+2 or 5-axis simultaneous machining is involved.

Benefit: Simple programming and high-precision milling of bottle shapes.

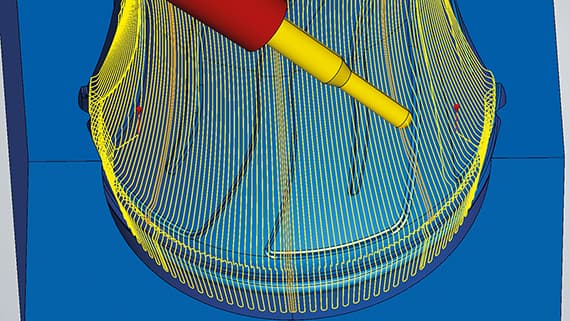

Smooth overlap: perfect transitions in indexed machining

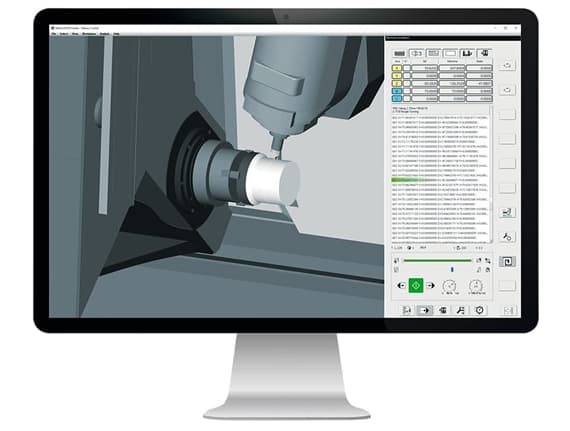

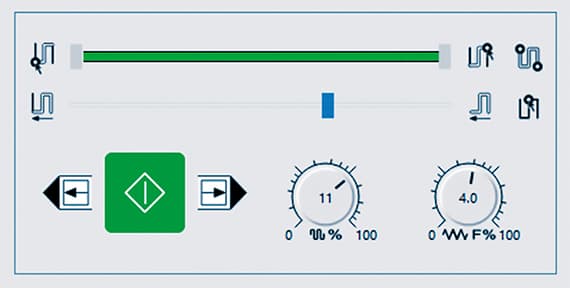

hyperMILL SIMULATION Center

Version 2021.1 provides a new, more powerful machine simulation for turning and milling operations. This means faster simulation, independent collision checking, and extensive analysis functions in an intuitive operating environment. The new hyperMILL SIMULATION Center is modeled on the look and feel of the hyperMILL VIRTUAL Machining Centers because our aim is to enable the CAM programmer to simulate as close to reality as possible.

Features

- Intuitive operating environment

- Independent collision checking

- More powerful and faster simulation

- Integrated in hyperMILL as standard

- Improved visibility control

Info: No postprocessor adaptation required, and existing machine models can continue to be used.

E-Learning content is available for the new hyperMILL SIMULATION Center. It can be accessed via the hyperMILL/Info tab.

Intuitive control

Transparent switching of elements by double-clicking

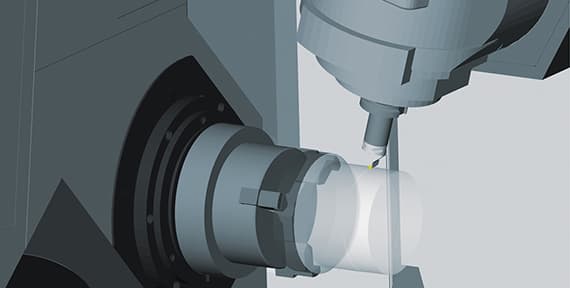

3-axis Simultaneous High Performance Turning

To combine all the advantages of HPC turning and simultaneous turning, the high-performance mode has been integrated into 3-axis Simultaneous Roughing. This makes it very easy to use high-performance toolpaths with optimized approach and retract movements during simultaneous turning. Simultaneous roughing is enhanced with the advantages of HPC turning at the push of a button, so combining both technologies with maximum user-friendliness.

Advantages

- Reduced machining time

- Increased process reliability

- Extended tool life

- Shorter clamped tools can be used

- Fewer tool changes

hyperMILL 2021.1 Videos

Click here to watch hyperMILL 2021.1 videos