As simple as a standard application

The Multiblade package.

Impellers and blisks can be programmed even without special knowledge using this application. Integrated automated functions in the Multiblade package reduce the number of parameters needing to be entered to a minimum. Proven collision checking guarantees a very high level of process reliability. The use of robust tools allows machining with high infeed parameters and feedrates.

![]() Download a hyperMILL 5AXIS Impeller/Blisk brochure1.06 MB

Download a hyperMILL 5AXIS Impeller/Blisk brochure1.06 MB

Milling of impellers and blisks made easy.

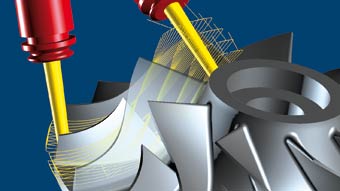

Multiblade roughing

In the roughing cycle, the blades are machined in a continual process starting from pre-turned stock or a semi-finished workpiece. No time-consuming simulation of the removal of material is required.

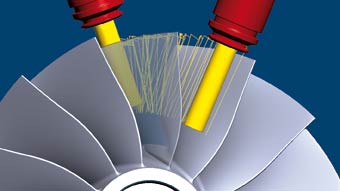

Multiblade plunge roughing

Plunge roughing is an alternative if a horizontal feedrate cannot be effectively machined with long, slim tools. This process allows the most rigid tool to be employed to rough open a pocket between blades, and is provided as an optional module.

Multiblade hub finishing

The tool path profile can adjust the hub’s aerodynamic behaviour and appearance to suit individual customer requirements. This machining strategy can also be applied as rest machining near blades.

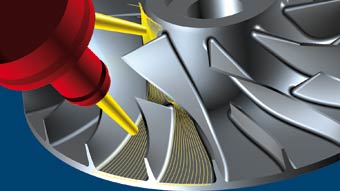

Multiblade point milling

This HSC strategy is characterised by continuous, spiral machining movements with tool point contact. This allows superb milling of even highly curved blades.

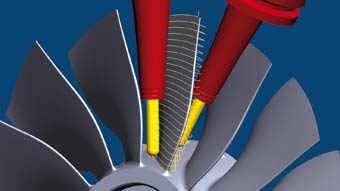

Multiblade flank milling

If the blade surfaces allow for sufficiently precise swarf cutting, the Flank Milling cycle can be used. This reduces machining time. hyperMILL® 5AXIS automatically calculates the optimal tool nestling.

Multiblade edge milling

This machining strategy is used whenever leading and trailing edges cannot be generated together with the flow areas in a single operation.

Multiblade fillet milling

This is the ideal strategy when the radii between the hub and the blade surfaces vary. This strategy also facilitates rest material machining – the basic requirement for choosing an optimal tool for blade and hub machining.