Standardise and automate

Programming with features.

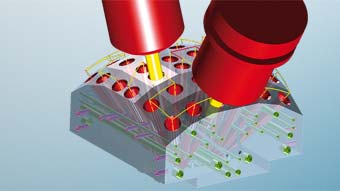

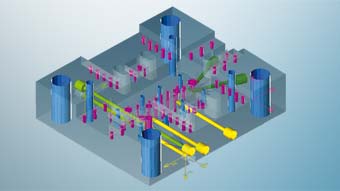

hyperMILL offers a broad array of options for CAD programming that utilise CAD geometry information (features) in a way that significantly reduces programming times. In addition to assigned geometries, features also include information relevant to machining, such as orientation, surface, depth or starting point. These are defined once and can then be assigned to the machining strategy. If the geometry or stored technology parameters are changed in the middle of a process, the changes need only be made in the feature. They are accounted for automatically when a new calculation is performed.

Customized Process Features enable the definition of company standards for similar geometries, thereby automating the programming process even more. This establishes workflows that are saved as technology macros. They can be used for comparable machining tasks. This is based on process-oriented links between characteristic geometries with freely definable sequences of various machining strategies – from 2D, 3D and 5axis milling to turning.

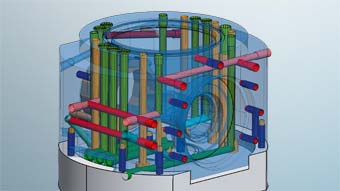

Automatic feature recognition

Detection of geometries, creation of boundaries, leading curves and profiles, as well as grouping of surfaces and holes

Pocket features

Automatic pocket recognition, even for pockets without bottoms

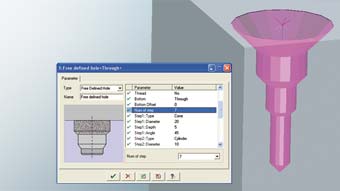

Hole features

Free definition of holes

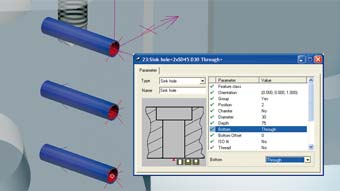

Hole features

Definition of simple holes as through holes or blind holes

Feature mapping

Importing of features from solids

Feature browser

Transparent display of different features or machining sides