At John Hart, we recognise that our relationship with the customer begins once a Mazak machine tool or system has been sold. We make every effort to fully support our products once they have been installed by offering a comprehensive range of support services to keep your Mazak running at full capacity.

Australia-wide machine tool service network

We have a thorough understanding of the importance of providing timely, reliable and skilled support for your machine tools. That is why we boast an Australia-wide Mazak service network with a team of highly experienced and qualified application, mechanical and electrical engineers.

Application Engineers

Application Engineers

John Hart’s team of factory trained Application Engineers draw on their extensive industry experience to offer detailed machining process analysis, process planning, cycle time studies and comprehensive on-site training on the correct operation of your Mazak machine tool.

Service Team

Service Team

John Hart’s service team comprises both Mechanical and Electrical Engineers. All engineers are Mazak factory trained to accurately install and, when necessary, carefully repair your Mazak machine tool. With engineers in each state of Australia, our team is on hand to rapidly respond to all of your service requests.

Preventative Maintenance

Preventative Maintenance

Regular, preventative maintenance is key to maintaining your Mazak machine tool in top working order and ensuring it’s long, accurate working life. John Hart’s preventative maintenance programs can be specifically tailored to your requirements and can be scheduled around your busy production schedules.

Mazak Certified Test Kits

Mazak Certified Test Kits

When installing or repairing your Mazak machine tool, John Hart Service Engineers utilize Mazak certified, regularly calibrated test kits and specialized calibration equipment. This allows the accurate installation, alignment, and configuration of your Mazak machine tool which ensures that your machine is set as the Mazak factory intended.

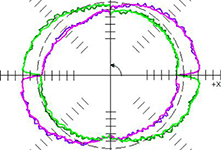

Ballbar Testing and Calibration

Ballbar Testing and Calibration

John Hart can perform a comprehensive diagnostic test and report utilising the Renishaw QC20-W wireless ballbar system and make calibration adjustments to improve the geometric performance of your CNC machine tool.

In-house Engineering

In-house Engineering

In addition to our Mazak support team, John Hart has a strong in-house engineering department. Our qualified engineers are on hand to assist with the development of specially engineered work-holding, cutting tool feasibility checks, automated machine tending or even the turn-key design and implementation of your next production cell.

Spare Parts Centre

Spare Parts Centre

John Harts well stocked Spare Parts Centre is staffed by our friendly team with comprehensive product knowledge. Our goal is to minimise your machine down-time, as we appreciate the importance of keeping spindles running. With Mazak factory support and direct online access to Mazaks World Parts Centre, we will almost certainly gain quick access to the parts you require to get your Mazak back online.

Mazak Spindle Exchange

Mazak Spindle Exchange

John Hart offers a Mazak factory service which allows non-functioning spindles to be replaced with genuine, as-new, factory specification exchange units. Mazaks spindle support factory in Japan stocks thousands of exchange spindles, both turning and milling, ready for immediate dispatch anywhere in Australia. Using a Mazak factory exchange spindle ensures your machine functions as it was designed and it includes all of the latest spindle improvements and upgrades.

Electronic Repair Facility

Electronic Repair Facility

With Mazak and Mitsubishi factory trained technicians, an expansive inventory, quick repair turnaround, an industry leading 12 month warranty on all repaired units, near zero return rate, and the latest testing and diagnostic equipment, John Harts Electronic Repair Facility and exchange program can have your Mazak back up and running fast should an electrical fault occur.