Optimised milling strategies for complete machining

The Blade package.

The Blade package provides many automations for simple machining definition and incredibly short programming times. These include the rolling ball function for milling transition radii, the best fit function for automatically setting the optimal start position for the finishing cycle or the automatic lead angle correction function for collision avoidance of the tool face with concave surfaces.

![]() Download a hyperMILL 5AXIS Turbine blade brochure854.23 KB

Download a hyperMILL 5AXIS Turbine blade brochure854.23 KB

Turbine blade milling – Complete from top to bottom.

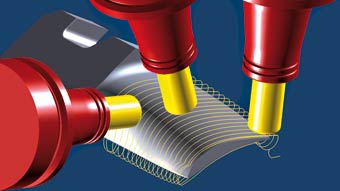

3D arbitrary stock roughing

On the basis of a freely definable stock, blades are machined from various directions.

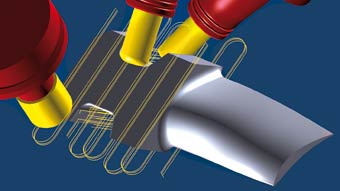

5axis blade top milling

This strategy is for finishing blade surfaces. It is possible to generate spiral tool paths as either 5axis or 4axis simultaneous machining operations using ball-end or bull-nose cutter.

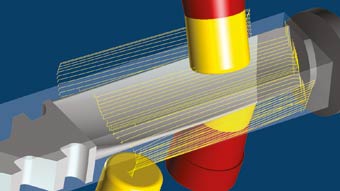

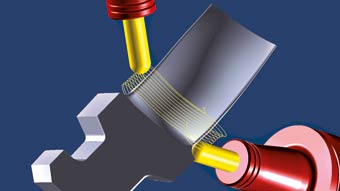

5axis blade swarf cutting

This strategy is used for the swarf cutting of platform surfaces. Swarf cutting can also be used to machine the transitions between the blade and the platform surfaces that cannot be machined using 5axis Top Milling.

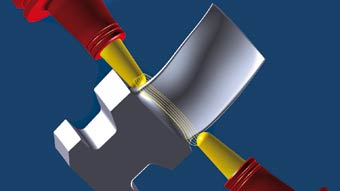

5axis blade fillet milling

This function optimises finishing at the transition between the blade and the platform surfaces of the tip or root.

Additional cycles for platform machining

A series of 2D and 3D strategies are available for machining the blade platform and root sections.