hyperMILL 2016.2 offers even greater performance and is easier to use than previous versions.

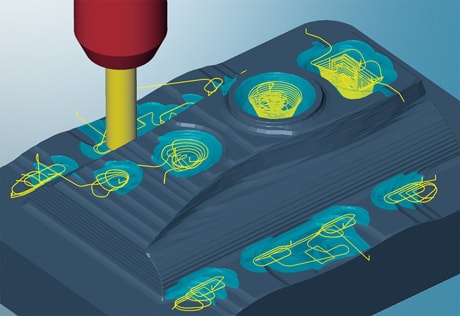

- The new 3D plane level machining and further optimisations for 3D milling enable more efficient programming.

- Highlights such as the 5 axis-optimised rest material roughing ensure extremely short calculation and machining times.

- 5 axis tangent machining has been added to the hyperMILL MAXX Machining performance package.

- In addition, hyperCAD-S once again includes numerous highlights and new features.

![]() Download a hyperMILL Version 2016.2 brochure6.58 MB

Download a hyperMILL Version 2016.2 brochure6.58 MB

What’s new in hyperMILL 2016.2

General

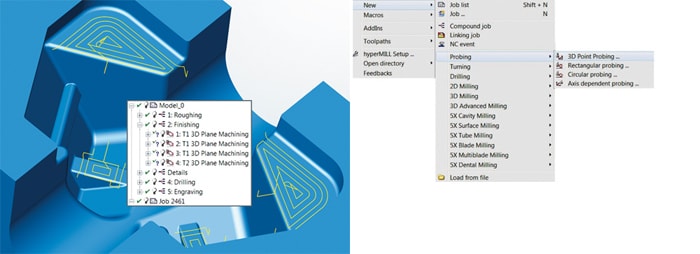

Optimised menu navigation

hyperMILL is even more user-friendly than before. A new shortcut menu ensures even simpler and faster programming. The menu windows are structured more clearly and feature new icons.

- Visibility of toolpaths: The toolpath display can be switched on and off using a visibility icon.

- Feature generation: Selected areas of a job, such as faces and contours, can be generated as a feature and reused in later jobs.

- Feature machining: You can now manually sort selected geometries in a feature and arrange them as required.

- Global clearance plane: You can globally define the clearance plane for a project, which is then adopted automatically for all jobs.

- Automatic report generation: The hyperVIEW® Report from hyperMILL can now be generated automatically with the click of a button.

JT format

hyperMILL supports the JT neutral 3D data format for importing model data. The JT format has become the industry standard, especially in the automobile industry.

Benefit: Fast import of JT data.

TDM Systems interface

The new integration in hyperMILL® enables fast data exchange with the TDM Systems tool management system.

Benefit: Easy to use, fast tool generation.

Tool database

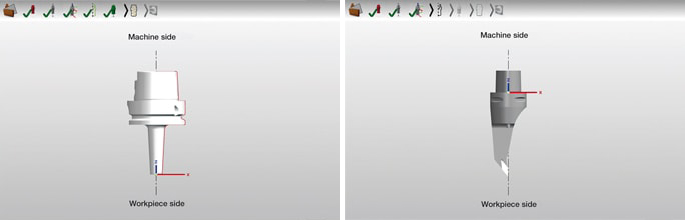

TOOL Builder

The new hyperMILL TOOL Builder allows you to quickly and easily create holders for machining in hyperMILL. An intuitive-to-use wizard allows you to directly import tool holder data from supplier catalogues in IGES or STEP format. The holders, extensions and turning tool holders generated can be assembled into an NC tool in the hyperMILL tool database. All components are fully checked for collisions. This way, tool holders and extensions for milling can be imported to hyperMILL with the original data from the supplier. hyperMILL millTURN tools such as holders and boring bars can now be imported 1:1 from the supplier catalogues. This allows complex holders to be mapped true-to-detail in hyperMILL.

Benefit: Simple and fast tool holder creation.

Stock management

Interactive stock chain

The user can create a stock chain for any number of jobs or for all jobs simultaneously. For each job, a resulting stock is generated for the previous job step. When a cycle is recalculated, stock is generated even for jobs that do not hold or carry stock.

Stock generation

A history is now created during manual stock generation. This allows you to keep track of which stock has been used for which job. This history can be updated at any time.

Stock display

There is an option for hyperMILL to automatically display the active job’s resulting stock and stock removal.

Benefit: Simpler programming, improved transparency.

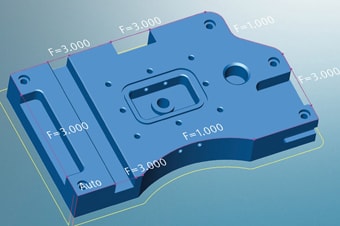

CAM – 2D strategies

2D contour milling on 3D models

A new feature for feedrate checking allows the feedrate to be adapted specifically for individual contour elements. You can define the feedrate for individual contours or specific segments on a contour. The ‘Edge control’ option allows the feedrate to be adapted automatically to the tool and component geometry.

Benefit: Protects the tool, simple programming, increased safety.

CAM – 3D strategies

3D plane level machining

This new cycle enables the finishing of planes. You select the area to be machined by making a simple selection of plane faces or via an automatic selection in the plane. The toolpaths can be optionally trimmed against a stock.

Benefit: User-friendly, fast programming.

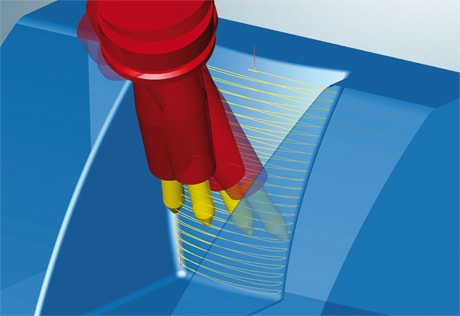

hyperMILL MAXX Machining

5 axis tangent machining*

5 axis tangent machining has been added to the hyperMILL MAXX Machining finishing module. The cycle now supports the conical barrel cutter for semi-finishing and finishing operations on any continuous faces.

Intelligent automated functions ensure optimum tool orientation and fit. In collision areas, the tool tilts upwards away from the contact point or guiding angle.

A new feature for Z-level and ISO machining enables simple selection of component surfaces. The cycle creates the toolpaths fully automatically without a special contour selection.

Benefit: Simple programming, faster finishing.

*Not included in maintenance contract.

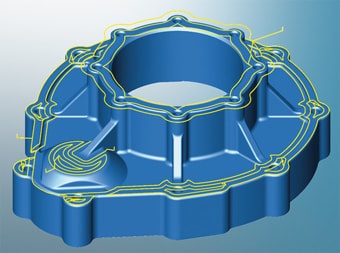

CAM – 5 axis strategies

Conical interpolation

The ‘Fast movement optimised’ option allows tools to be positioned around the pole in conical movements. This prevents singularities and generates simultaneous 5axis movement. Most machine tools can carry out this movement much more dynamically.

Benefit: Shorter machine times, movements are easier on the machine tool.

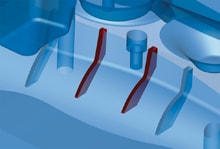

5 axis optimised rest roughing*

This new cycle generates high-speed cutting (HSC)-optimised toolpaths for rest material machining, based on a preceding roughing operation. An advantage of indexed 5 axis machining is that you can use shorter tools that guarantee higher stability and greater performance. The strategy is especially efficient for cavities and hard-to-reach areas.

Indexed machining

You can define the tilt angles for the B and C axes easily and quickly using two modes. The ‘Planes’ option allows you generate the tilt angle from the plane normals. In ‘3D mode’, tilt angles are generated automatically within a defined range of angles. All connecting paths between the tilt angles are optimised and fully checked for collisions.

Benefit: Machine-friendly, tool-friendly, extremely short machining and calculation times.

*Not included in maintenance contract.

CAD integration: hyperCAD-S

Wrapping

The new ‘Wrapping’ command allows you to wrap plane curves or texts onto cylindrical and rotational faces. The wrapping does not distort the geometry. The direction, scaling and mirroring can be modified.

Benefit: Fast generation and milling of engraved contours.

Compare and merge

This function allows the user to compare various versions of CAD models and select modified geometry elements to insert them into an existing document. All unmodified geometries remain in hyperMILL so only updated areas need to be reprogrammed.

Benefit: New versions can be adopted automatically by an existing document.

Markups

The new function improves communication between hyperMILL programming workstations and hyperMILL SHOP Viewer workstations. The user has the option to highlight areas in a model and add text information to these areas. The profile and machining status are documented and can be checked at every workstation using a preview. Markups can also be used in read-only documents in hyperMILL SHOP Viewer.

Benefit: Easier exchange of machining tips and information.

Convert to analytical

The NURBS elements of faces and curves are converted to analytic elements such as lines, arcs, cylinder faces, rotational faces and planes. Splines are converted to lines and arcs, for example. This conversion enables faster, smoother machining.

Benefit: Simple conversion of NURBS elements, better milling

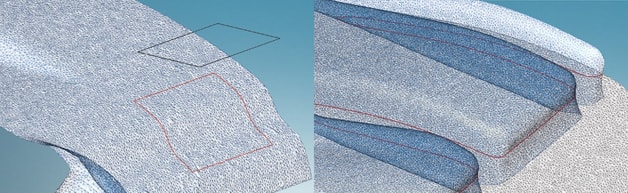

Mesh functions

The ‘Project’ command allows curves to be projected onto a mesh surface, and then be used as a boundary entity for hyperMILL® programming.

The ‘Intersect curve’ command allows cutting curves to be created between two meshes.

Benefit: Easy preparation of meshes for milling.