Losma DTE coolant filter, neat oils filtration, emulsion filtration, industrial coolant filtration, machine tool coolant filtration.

Losma DTE is a flatbed coolant filter, using non-woven fabric for eliminating magnetic and non-magnetic particles from neat oil and emulsion.

- Filtration degree determined by the choice of the fabric ranging from 10 to 50 microns.

- Reliable and versatile system

- Available in stainless steel version.

Unit tested

Losma guarantees that every single unit is individually tested through strict control procedures. Each unit is issued a test certificate for quality and function.

Economical

Fabric media filtration guarantees a high filtration efficiency with a limited initial investment..

Technical information

Losma DTE filtration degree can be determined by the choice of the fabric, ranging from 10 to 50 microns, granting the highest level of filtration. Losma DTE is available in 12 sizes, with a flowrate capacity from 50 to 400 l/min of emulsion and from 25 to 200 l/min of neat oil.

Operation

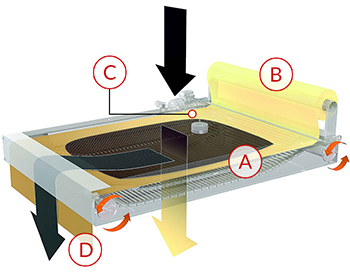

- The dirty coolant falls into the distribution trough (A) and from here onto the filter fabric (B) which retains solid pollutant particles (dust and swarfs) while the filtered oil passes through it.

- The fabric collects progressively the pollutant, until losing its filtering capacity. At this stage the liquid collects on the through and lifts the float (C) and starts an automatic system, which advances the collection tray to change the exhausted fabric with the new one.

- Exhausted fabric (D) is collected in a dedicated tank. The clean liquid is collected the tank below (E), in order to be pumped back to the machine tool.

Optional

1. Skim

Superficial oil skimmer, it allows to lengthen coolant quality and eliminate odors generated by anaerobic bacteria.

2. DMD

Pre-filtration system with rotating magnetic discs for the separation of magnetic polluting particles from coolant.

3. Electrical panel

For powering the system, control and command all signals.

4. Colleting tank

For clean liquid collection, to be sent back to the machine tool.

5. Transfer tank

To collect dirty liquid for feeding the filter

6. Pump

For pressure from 0,1 to 100 bar for returning clean liquid.