Losma Darwin oil mist collector, oil mist filter, fume separator, dust collector, industrial air filter, machine tool air filter.

Losma Darwin is a range of centrifugal oil mist filters for cleaning air containing oil mists, micro-mists and smokes produced when using coolants (emulsion or neat oil). It has been designed to be mounted on or off the machine.

- It is available in 4 sizes, for a flowrate up to 3000 m³/h, with 3 different interchangeable filtration technologies.

- It can be mounted horizontally or vertically

- Double filtration system

- Easy installation

- Stainless steel version

Unit tested

Losma grants that every single system is tasted through strict control procedures. Every unit is provided with a qualitative and functional test certificate.

Fast and easy maintenance

Access to the filtration section is very easy and quick, without having to unscrew or disassemble anything.

Condensation and drainage

Darwin series grants incomparable capacity of re-condensation and drainage of filters and liquids which may then collected and recycled.

Technical information

It is available in 4 sizes with three different, interchangeable filtration technologies:

- Turbina: suitable for surface machining also in the presence of heavy particulates

- Mono centrifuge: suitable for all machining processes

- Double centrifuge: suitable for all machining processes above all heavy machining conditions like use of high pressure.

Throughputs available are from 600 to 3.000 m3/h, with different combination for increasing filtration efficiency, up to 99,97%.

Operation

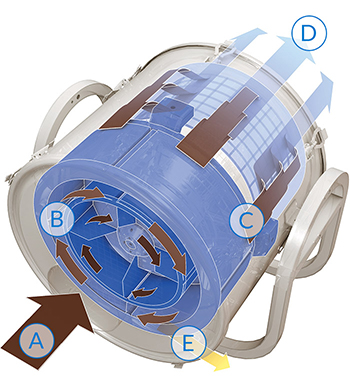

- Polluted air is drawn into the system (A) thanks to the depression generated from the rotation of the centrifuge (B), which gives the air a swirling movement.

- Air passes through the special expanded polyurethane foam inserts positioned in the centrifuge (only in mono and double version) and then into a net. The combination of all these elements facilitates the re-coalescing of oil particles – including the finer ones.

- Air crosses a further static filtration layer (C) before being re-introduced into the working environment (D). The re-condensed liquid is eliminated through the drainage tube in constant positive pressure (E).

- Darwin series grants a filtration efficiency of over 95%, also for pollutant particles below one micron; this efficiency rate can be increased to 99,97% with the use of an absolute post-filter (HEPA FILTER) according to EN 1822 norms.

Optional

1. Clipper

Available with F9 filtration level (95%) or H13 efficiency, up to 99,97% following EN 1822 norms. Useful in case of micro-mists and smoke.

2. Guard

Pre-filtration module for swarf, chips and dust, working through metallic and synthetic filtration stages. Useful to optimize the air suction efficiency in case of high production of oil mists containing dusts and metallic swarf chips.