Next generation 5-axis machining center for full automatic operation over extended periods

- Wide variety of spindles to meet a wide range of requirements in industries

- Provides exceptionally wide machining area for handling large workpieces or jigs

- Tilting / rotary table plus high rigidity machine construction ensure high-accuracy machining over extended periods of operation

- New MAZATROL SmoothAi CNC system

Spindle

Spindle specifications to meet a wide variety of machining requirements

10000 min-1 Standard

| Spindle motor (40% ED) | : 37 kW (50 HP) |

| Max. torque (40% ED) | : 350 N・m |

| Tool shank | : BT-50, BBT-50, HSK-A100 |

7000 min-1 High-torque

| Spindle motor (40% ED) | : 30 kW (40 HP) |

| Max. torque (40% ED) | : 442 N・m |

| Tool shank | : BT-50, BBT-50, HSK-A100 |

18000 min-1 High-speed (HSK-A100 / HSK-A63)

| Spindle motor (40% ED) | : 55 kW (74 HP) 35kW (47 HP) |

| Max. torque (40% ED) | : 105 N・m / 134 N・m |

25000 min-1 High-speed

| Spindle motor (40% ED) | : 23 kW (31 HP) |

| Max. torque (40% ED) | : 22 N・m |

| Tool shank | : HSK-A63 |

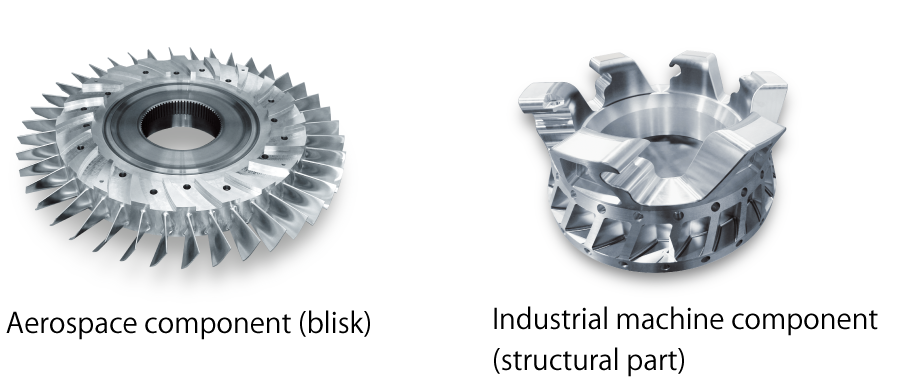

Applications

Effective process integration by 5-axis to reduce cycle times

The stroke of X, Y, Z-axis is much longer and the rapid traverse rate is much faster than previous models. A variety of workpiece can be machined effectively.

Next generation MAZATROL Smooth CNC system

![]()

Machine Specifications

| Mazak Variaxis i-800 NEO | Values | |

| Spindle | Spindle Taper | BT50 |

| Maximum Speed | 10000 rpm | |

| Magazine | Number of Tools | 30 |

| Rotary Axes | Table Tilt (A axis) | 150 degrees |

| Table Indexing (C axis) | 360.0000 degrees | |

| Feed Axes | Travel (X Axis) | 750 mm / 29.53 in |

| Travel (Y Axis) | 890 mm / 35.04 in | |

| Travel (Z Axis) | 600 mm / 23.62 in | |