Compact high speed horizontal machining center for mass production

- High productivity

Reduced non-cutting time thanks to high speed acceleration and rapid traverse rate.Feedrate (X, Y, Z-axes) 62000 mm/min Max. acceleration (X-axes) 0.6 G (Y-axes) 0.8 G (Z-axes) 1.2 G Spindle acceleration time 1.3sec (0→12000min-1) - High reliability

All machine linear motion is in the column to isolate the ball screws from machined chips.

Tools are directly changed to/from the spindle to the tool magazine to ensure high reliabiliy. - Automation

Fixed table construction provides convenient automatic fixture mounting for exceptional versatility.

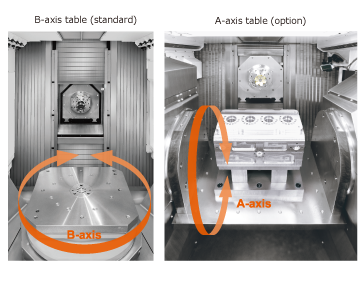

Machines with the standard B-axis machine and machines with the optional A-axis can be integrated in the same production line.

- MAZATROL SmoothC, the advanced CNC designed for ease of operation - standard equipment

- The MAZATROL SmoothC CNC is standard equipment and the Fanuc 32i is optionally available.

Note : Thermal Shield depends on market.

Machine Specifications

| Mazak FF-5000/50 | Values | |

| Capacity | Pallet Size | 500 mm / 19.690 in |

| Maximum Workpiece Diameter | 720 mm / 28.350 in | |

| Maximum Workpiece Height | 870 mm / 34.250 in | |

| Spindle | Spindle Taper | BT50 |

| Maximum Speed | 10000 rpm | |

| Magazine | Number of Tools | 20 |

| Feed Axes | Travel (X Axis) | 660 mm / 25.98 in |

| Travel (Y Axis) | 660 mm / 25.98 in | |

| Travel (Z Axis) | 555 mm / 21.85 in | |