The metal cutting industry has long understood 5-axis technology as a transformative technology, one that allows for the creation of parts that would be impossible to cut with conventional machines.

More axes means greater productivity

Many machine shops have invested in 5-axis technology without clear part-production goals in mind, as the technology can be a valuable way for a machine shop to set itself apart from its competitors or expand its customer base. Others choose to continue using stable 3-axis processes, believing they do not need or cannot afford 5-axis capabilities.

In reality, 5-axis machining, especially full simultaneous 5-axis machining, can provide significant value to nearly any machine shop, and the range of equipment available today allows nearly any manufacturer to experience the benefits of the technology. From repeatability and precision to savings on work-holding and setup time, 5-axis machining makes ordinary parts even faster to machine, in addition to allowing for more complex parts. Furthermore, improvements in control technology and offline programming have made these machines much more accessible to program and use.

A brief history of 5-axis machining

Although many manufacturing professionals discuss 5-axis technology as a relatively new innovation, multi-axis machining pre-dates even numerical control, let alone the sophisticated CNC machines seen in today’s shops. As with screw or Swiss-style machines, early versions of this equipment required substantial setup time, in exchange for quick mass production of relatively complex parts. However, digitization made 3-axis mills and lathes much more practical for most general machining, particularly when the programming requirements for eventual 5-axis CNC machines appeared prohibitive for many shops.

Many machine tool OEMs addressed this problem with so-called “3+2” machining, in which the machine executes a 3-axis milling program after locking the cutting tool in a tilted position with its two rotational axes. Also known as 5-axis positional machining, this style of machining is not capable of creating the complex contours that 5-axis technology is known for, but it provides other advantages, such as removing the need for fixturing to drill angled holes. Many machine shops saw this as a bridge technology between conventional and full 5-axis machining because of its somewhat lower prices, but as the cost of more advanced equipment has fallen, the need for a cheaper alternative to full 5-axis machining has also decreased.

Mazak machines focus on simultaneous 5-axis technology, where the rotating and tilting table operates independently from the three linear axes, allowing them to move in concert to produce unique part shapes and features. This reduces the need for fixturing even further, contributing to higher throughput and shorter lead times. The high-precision tilting and rotating tables ensure repeatable, predictable positioning without the need for additional manual part movement.

Selecting and applying 5-axis technology

A wide range of 5-axis machines ensures that all machine shops have access to the technology, as well as solutions that can meet their unique needs. But it also makes choosing the correct machine that much more critical.

To achieve the lowest possible cost of ownership, your investment should match your anticipated needs as closely as possible, even while you consider a range of other factors specific to 5-axis machines.

From an application standpoint, for example, the expanded range of angular motion requires a larger work envelope than one might expect. To machine 300mm cube, you may need a 450mm cube of clearance. Likewise, tools must often be longer to accommodate various angular machining applications, which might prompt shops to select a larger taper or more advanced tool-holding, such as shrink-fit or hydraulic solutions.

Programming for 5-axis machines has also become much easier, but the use of CAM software remains necessary. MAZATROL Smooth controls and associated SMOOTH TECHNOLOGY software packages can simplify this, as they are designed to work with a complete range of CAD/CAM environments. With MAZATROL TWINS and SMOOTH Project Manager, for example, programmers have full access to virtual machines from their office desktop computers, and a seamless program management system speeds up later program distribution and execution.

Access, accuracy, and agility

At its core, 5-axis technology offers very simple advantages that can make it valuable in nearly every machine shop environment, despite its additional complexities.

With 3-axis machines, machine shops often must stop production to turn or re-clamp a part into a custom-built fixture so they can handle a compound angle or diagonal part wall. A 5-axis machine can simply be programmed to tilt the table, allowing the same degree of access with the benefit of error-free, machine-controlled movement that can be relied upon across many jobs.

As a result, machine shops that integrate even entry-level 5-axis technology see its benefits quickly. What required multiple setups can often be finished in two, as these machines can work on five faces of a given part at once. The setup-time improvements alone can contribute to much shorter lead times, while increased repeatability prevents damaged or scrapped parts from impacting productivity. These advantages are especially potent in machine shops with high-mix, low-volume production environments, where agility is critical to keep up with the fast turnaround times their customers expect.

Mazak Variaxis C-600

The Mazak Variaxis C-600 simultaneous 5-axis vertical machining center uses rigid C-frame construction, a standard 30-tool changer, dual-supported tilting table and fast rapid traverse rates to reduce cycle times on demanding jobs. It accepts a wide range of spindles, including high-speed and high-torque options, to produce a wide range of parts from steel and non-ferrous metals. Its MAZATROL SmoothAi CNC adds efficiency and value, with a wide variety of advanced programming functions for complete ease of use and repeatable high-accuracy performance.

Click here to see a Mazak Variaxis C-600 machining demonstration video.

|

Mazak Variaxis C-600 specifications |

||

|

Capacity |

Maximum Workpiece Diameter |

730 mm |

|

Maximum Workpiece Height |

450 mm |

|

|

Spindle |

Spindle Taper |

40 |

|

Maximum Speed |

12000 rpm |

|

|

Motor Output (30 minute rating) |

11 kw |

|

|

Magazine |

Number of Tools |

30 |

|

Rotary Axes |

Spindle Tilt (B axis) |

150 degrees |

|

Table Indexing (C axis) |

360.0000 degrees |

|

|

Feed Axes |

Travel (X Axis) |

650 mm |

|

Travel (Y Axis) |

550 mm |

|

|

Travel (Z Axis) |

530 mm |

|

Expanded capabilities

The phrase “complex contours” can be found in nearly every description of 5-axis technology for a reason – this approach makes many parts possible that could not be produced with conventional machines. Nevertheless, 5-axis machines can also expand a shop’s capabilities in a variety of other ways that may be more surprising. In addition to the kinds of process consolidation discussed above, these machines can also vastly improve the manufacturability of various products.

These capabilities were pioneered in the aerospace industry, where complex assemblies are common.

A given component might require 15 to 20 different parts, all with tight tolerances for fit and geometric complexities required for final assembly. With 5-axis technology, none of this becomes necessary.

Contouring, compound angles and innovative approaches to machining make it possible to produce these assemblies as single pieces. Every industry now has access to this kind of streamlining, and given the costs of maintaining large part families, 5-axis capabilities can result in significant savings.

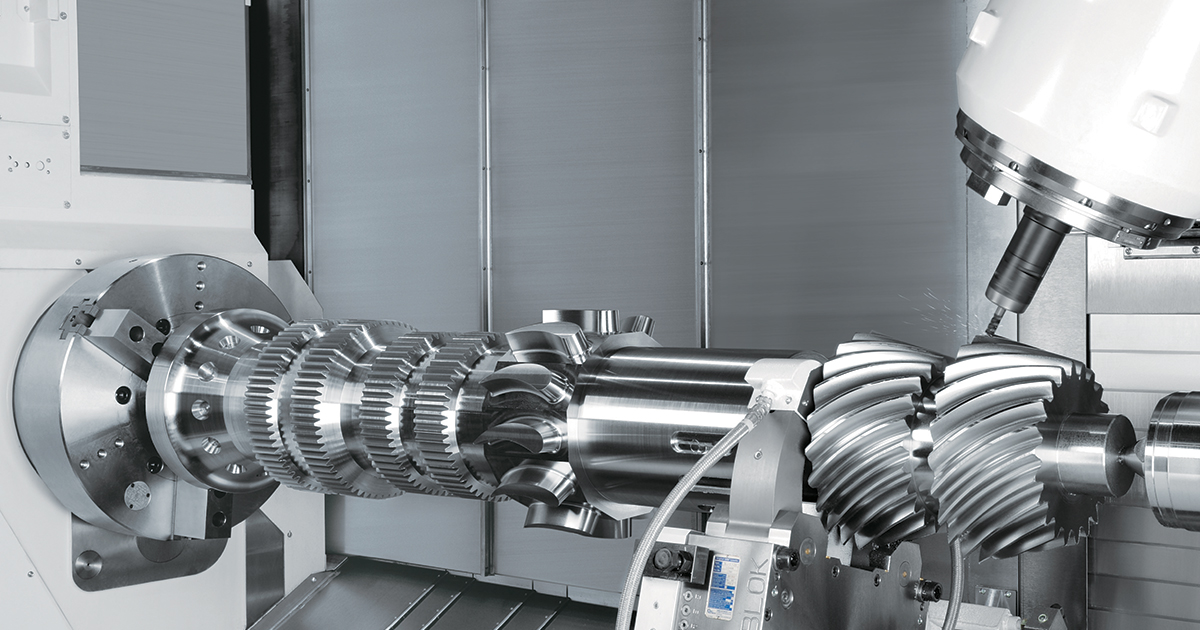

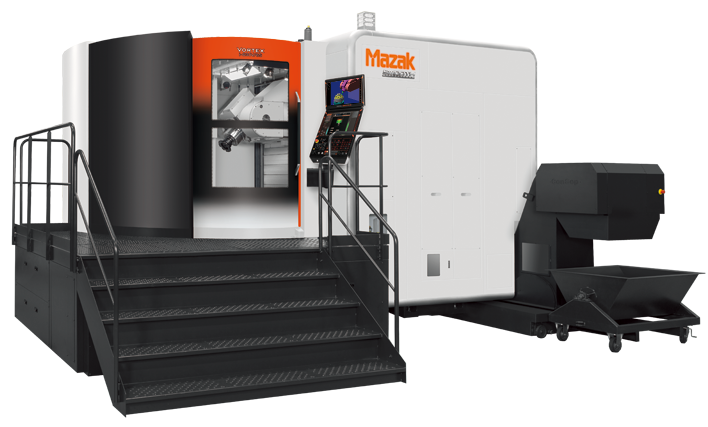

Mazak Vortex Series

When machine shops need unsurpassed accuracy for the production of large, heavy parts, they often choose from the Mazak Vortex Series, robust machine models built around highly symmetrical base-and-column designs and/or tilting spindles with rotating tables. This allows for outstanding precision for cutting even large and complex titanium, aluminum and steel components such as jet engine casings, air frame components and gearboxes.

Mazak Vortex i-630V/6S

Perfect for job shops and advanced manufacturers alike, the single-table Mazak Vortex i-630V/6S offers standard, high-speed and high-torque spindle specifications to successfully meet a wide variety of application requirements.

Click here to see a Mazak Vortex i-630V/6S machining demonstration video.

|

Mazak Vortex i-630V/6S specifications |

||

|

Capacity |

Maximum Workpiece Diameter |

1250 mm |

|

Maximum Workpiece Height |

1400 mm |

|

|

Spindle |

Spindle Taper |

50 |

|

Maximum Speed |

10,000 rpm |

|

|

Motor Output (30-minute rating) |

37 kw |

|

|

Magazine |

Number of Tools |

43 |

|

Rotary Axes |

Table Tilt (B axis) |

150 degrees |

|

Table Indexing (C axis) |

360.0000 degrees |

|

|

Feed Axes |

Travel (X Axis) |

1425 mm |

|

Travel (Y Axis) |

1050 mm |

|

|

Travel (Z Axis) |

1050 mm |

|

Mazak Vortex Horizontal Profiler 160 XP

With a massive 4000 mm x 1600 mm vertically oriented rotary/tilt worktable that accommodates up to 3000 kg, this rugged machine and its high-speed spindle options bring unmatched power, speed and accuracy for medium and large-sized parts.

Click here to see a Mazak Vortex Horizontal Profiler 160 XP machining demonstration video.

|

Mazak Vortex Horizontal Profiler 160 XP specifications |

||

|

Capacity |

Table Right/Left |

4000 mm |

|

Table Longitudinal |

1600 mm |

|

|

Spindle |

Spindle Taper |

HSK-A63/80mz |

|

Maximum Speed |

30,000 rpm |

|

|

Magazine |

Number of Tools |

60 |

|

Feed Axes |

Travel (X Axis) |

4200 mm |

|

Travel (Y Axis) |

1500 mm |

|

|

Travel (Z Axis) |

550 mm |

|

5-axis multi-tasking

In many ways, 5-axis technology matured in tandem with multi-tasking technology, the other major form of process consolidation that took place in the metal cutting industry’s recent history. It therefore comes as little surprise that the two solutions can be combined for even greater processing versatility – particularly given the popularity of the Mazak Integrex Series, Mazak’s flagship line of multi-tasking machines.

These complementary technologies are what make DONE IN ONE machining possible. Part hand-off between spindles prevents the need for nearly all manual workpiece handling, as it allows access to the unmachined sixth side. A Mazak Integrex machine can act as a horizontal 5-axis solution with ease, even for shops that rarely need its turning capabilities – and the same holds true for Mazak’s other models of larger 5-axis machines that also offer turning capabilities.

While many manufacturers leverage the capabilities of a Mazak Integrex as a way to integrate bar-feeding automation into non-turning applications, multi-tasking technology allows for many similar forms of simple in-machine automation. But 5-axis machines also work well with other kinds of automation.

Many Mazak machines, for example, offer 2-pallet configurations that enable machining to continue while workpieces are loaded and unloaded on the other pallet.

More advanced solutions, like the Mazak Multi-Pallet Pool (MPP) and the Mazak PALLETECH systems, enable full unattended, lights-out machining.

Mazak Integrex i-250H ST

Designed to offer the highest level of single-setup part-production versatility available today, the Mazak Integrex i-250H ST multi-tasking center features a second turning spindle (S) and lower parallel-style turret (T) with optional rotary tool capabilities to minimize fixtures, tools, handling and non-cut time. It also includes the next-generation MAZATROL SmoothAi CNC, which provides exceptional programming and production efficiency thanks to advanced features such as MAZATROL TWINS.

Click here to see a Mazak Integrex i-450H ST machining demonstration video.

|

Mazak Integrex i-250H ST specifications |

||

|

Capacity |

Maximum Swing |

670 mm |

|

Maximum Machining Diameter |

670 mm |

|

|

Maximum Bar Work Capacity |

65 mm |

|

|

Maximum Machining Length |

1519 mm |

|

|

Main Spindle |

Chuck Size |

8 in |

|

Maximum Speed |

5000 rpm |

|

|

Second Spindle |

Chuck Size |

8 in |

|

Maximum Speed |

5000 rpm |

|

|

Milling Spindle |

B-Axis Travel |

240 |

|

Magazine Capacity |

38 |

|

|

Maximum Speed |

12000 rpm |

|

|

Turret (Lower) |

Number of Tools |

12 |

|

Feed Axes |

Travel (X Axis) |

695 mm |

|

Travel (X2 Axis) |

220 mm |

|

|

Travel (Y Axis) |

300 mm |

|

|

Travel (Z Axis) |

1585 mm |

|

|

Travel (Z2 Axis) |

1539 mm |

|

Conclusion

Manufacturing professionals have always understood that 5-axis technology represents the future of metal cutting – and that future is now. Retaining old processes, however reliable they may have been, is counterproductive when it has become easy to find productivity and quality-enhancing 5-axis solutions within the reach of any machine shop, including several best-in-class Mazak models. As many manufacturers have discovered, there has never been a better time to expand their capabilities as they prepare for the next wave of product development and production.