Axiom Precision Manufacturing is one of many manufacturers thriving in South Australia’s fast-growing defence and aerospace sector. We spoke to Craig Maynard, the General Manager of Axiom Precision Manufacturing, to get an insight into their significant machine tool investments plus the company’s recently completed, and purpose built, manufacturing facility.

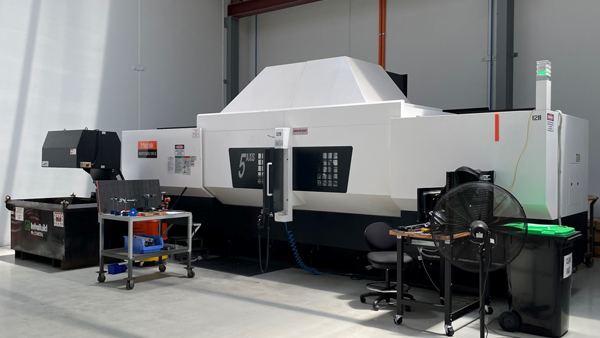

Axiom's Mazak Integrex e-1250V/8

Axiom began as a manufacturer for the automotive industry in 1979, and transitioned to defence and aerospace manufacturing during the early 2000s, in anticipation of the auto industry shutdowns.

The company has a long-term relationship with John Hart and relies on its local support to get the most out of the cutting-edge features provided by Mazak and hyperMILL aerospace technology, as well as the local service team being on-site within hours to keep their machine tools in production.

Axiom has always demanded machine tools that are strong, accurate, and reliable, which is one of the main reasons it continues to choose Mazak. In the last year alone the company added a Mazak Vortex 815/120-II, a Mazak Integrex e-1250V/8, a Mazak Integrex i-200S, a Mazak Integrex i-300S and a Mazak Variaxis j-600/5X to its already impressive fleet of Mazaks. Axiom also invested in a hyperMILL CAM system.

The Vortex 815/120-II vertical machining centre delivers high productivity through full simultaneous five-axis machining and multiple surface machining capabilities. The machine is specifically designed for the aerospace industry and features a large table for processing large complex workpieces often found in that sector. It is only the second machine of its type in the country and fulfils Axiom’s requirement for producing titanium airframe components. Axiom purchased the Vortex 815/120-II to support additional work on the JSF-F35 program, providing the additional capacity required for machining the 2.7-metre long Leading Edge Spar for BAE Systems Australia.

The other machines were purchased to provide the capability and capacity required to support future defence and aerospace projects. Mazak’s Integrex e-1250V/8 multi-tasking machine combines full five-axis machining, heavy-duty turning operations and palletchanging capabilities to productively process large, complex parts such as jet engine casings and gearboxes from titanium, aluminium and steel. Because the machine can perform milling, turning, boring and drilling in single set-ups, manufacturers can reduce the inaccuracies caused by moving heavy parts between workstations, and eliminate work-in-process inventory.

Both the Integrex i-200S and Integrex i-300S multi-tasking machines combine a turning centre and machining centre for full five-axis machining and productive manufacturing.

The Mazak Variaxis j-600/5X vertical machining centre, with its high precision rotary/tilt table, handles all processes from raw material input through final machining to provide dramatic reductions in lead times and improve workpiece accuracy by eliminating multiple setups.

Axioms Mazak Vortex 815/120-II

“These five machines, along with our existing Mazak Integrex i-800V/8, have been commissioned in our recently completed 2,000sqm facility, built to Zone 3 Defence security requirements. With the broad range of machining capabilities these machines offer, along with being in a secure facility we can manufacture almost anything required by the Defence and Aerospace sector.”

Axiom always consider all the available options when purchasing new CNC machinery. Maynard detailed why Axiom chose Mazak over other brands : “One of the reasons is the support we receive during the install, commissioning, training and ongoing maintenance. The John Hart team offer fantastic support for all our Mazak CNC machines, whether they be new or older machines. The other reason we selected these machine is the capabilities we were looking for, along with the value for money we get with Mazak."

Craig explained Axiom’s relationship with John Hart: “With the delivery demands of aerospace programs we can’t afford for machines to be down for any period of time; this makes service support critical to maintaining component supply. John Hart always respond promptly to our business needs, keeping the CNC machines running to meet our customers’ needs.”

Mazak fleet growing at Axiom's defence manufacturing facility

“John Hart engineers also have a thorough understanding of the unique applications of machine tools and technologies required to process various components from titanium, heat-resistant super alloys, aluminium or stainless steels. John Hart engineers are available to discuss specific part challenges and how Mazak technologies make machining these complex parts easier and more efficient.”