ACIM is a Melbourne based manufacturing company managed by husband and wife team, Anthony and Lisa Coleman. The Company specialises in designing and manufacturing inflatable packers, hydraulic fracturing systems, tools and data loggers for the geotechnical, mining, oil and gas markets. Established in 1990, the company has grown from humble beginnings servicing the Australian market, to a company that now sells into many international markets such as Chile, South Korea, Italy, Russia, America and Indonesia.

Anthony Coleman in front of ACIMs Mazak VTC 530/20

ACIM in-house designed products are recognised by customers for being innovative and of the highest quality. Their products regularly out-perform larger and more established competitors and they say a key reason for this success is their investment in Mazak CNC Machine Tools.

In 2013 when ACIM decided to bring manufacturing in-house, they gave John Hart the opportunity to offer a solution to suit their production and budget requirements.

As a result, they invested in a Mazak Quick Turn Smart 350M multi-function lathe with milling. The machine combines productivity, high accuracy and high reliability handling parts up to 420mm in diameter and 1250mm in length.

Anthony Coleman explains, “Programming was the main reason we selected a Mazak Quick Turn Smart 350M. It has proven to be very easy to learn, and being a small business we were under pressure to make good on our investment and produce parts straight away. John Hart showed us how to get the jobs started and we became comfortable using the machine faster than expected.”

Anthony adds, “Bringing manufacturing in-house also enabled us to respond quickly to our client’s customisation needs. The Quick Turn Smart has driven our development further, improved our designs, enabled testing, and allowed us to do it all in-house.”

The benefits brought about by the Quick Turn Smart investment resulted in business growth triggering the purchase of a Mazak VTC-530/20 in 2019, a high speed and high accuracy travelling column vertical machining center.

Ian Swan, John Hart Victorian Branch Manager commented, “The VTC-530/20 was not only an innovative solution but also an alternative machine solution to the one that was originally considered by ACIM. The new machine facilitated the move of a majority of the milling from the Quick Turn Smart to the VTC-530/20 for improved machine utilisation and increased production.”

The long 2300 mm x 530 mm table provides exceptional versatility. An optional center partition allows the VTC-530/20 to be used like two separate machines. Part setup can be performed on one side of the partition while workpiece machining is being performed on the other.

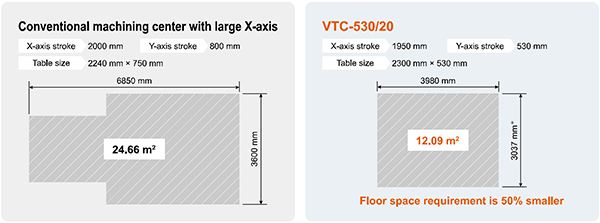

A compact machine footprint was another important factor for ACIM. The VTC-530/20 boasts a 50% smaller footprint than conventional machining centres with a similarly large X-axis stroke of 1950mm.

The two Mazaks working together has enabled ACIM to further enhance their production processes, cut down production costs and reduce overall manufacturing time. A good example of the advantages of their Mazak machines was a recent job which Anthony explains; “A customer requested a custom mining tool, with a tight turnaround. The product needed to be designed from scratch, manufactured, tested and delivered to NSW in less than two weeks.” Achieving such a tight delivery requirement was historically not possible, but with their world class Mazak machine tools the job was done and the customer happy.

At the time of considering the Mazak VTC-530/20, ACIM also evaluated the feasibility of using a CAM solution to make programs directly from the CAD software. The CAM system would complement Mazatrol programming by accessing the information and intelligence built into a 3D model and make programming faster, easier and less error prone. A CAM system was also required to generate 3D toolpaths. Anthony looked into the leading CAM software options and selected hyperMILL due to its cutting-edge technology and high level of John Hart support.

Talking about this decision, Anthony and Lisa Coleman summarised their relationship with John Hart, “The people at John Hart work hard to provide our company with world class technology and world class value backed by world class service. It is clear to us that they tie their success to our success.”