Mazak multi-tasking technology helps improve quality of life, and productivity.

In an industry heavily dominated by wealthy American and European manufacturing companies, one Australian owned manufacturer, Adelaide based Austofix, is leading the way in the development and distribution of medical devices for the treatment of orthopaedic trauma and osteoporosis.

Established in 1993 by Dr Tony Ingman, an orthopaedic surgeon who grew up amongst a family of engineers, Austofix has grown rapidly from a small family run business with limited facilities, to a publicly listed company that boasts its own state-of-the-art manufacturing facility.

The past 15 years has seen a diversification in the company’s product range, a progression brought about largely by the adoption of CNC machinery. In the early days, pins and screws used for treating bone fractures were produced on a capstan lathe, a manually operated centre lathe and several pedestal drills. With the purchase of their first CNC lathes in the late 90’s, including a second-hand Mazak QuickTurn 10N, Austofix were able to start prototyping and producing more sophisticated and complex parts like bone plates, as well as being able to undertake a variety of contract work for other medical products. This increase in capabilities was reflected in the strong growth of the company.

However, to make it possible for Austofix to continue to harness innovation and open up new markets for their products, they needed to be able to take those products from concept to the market quicker than their competitors. According to David Entwistle, Director of Manufacturing at Austofix, “CNC machining and the development of harder cutting tools have enabled the economical manufacture of increasingly intricate products made from tough materials.” David further explains that this means “more and more bone fractures can be treated with surgical implants, resulting in better outcomes for patients and shorter hospital stays”, a desirable prospect for patients and hospitals alike.

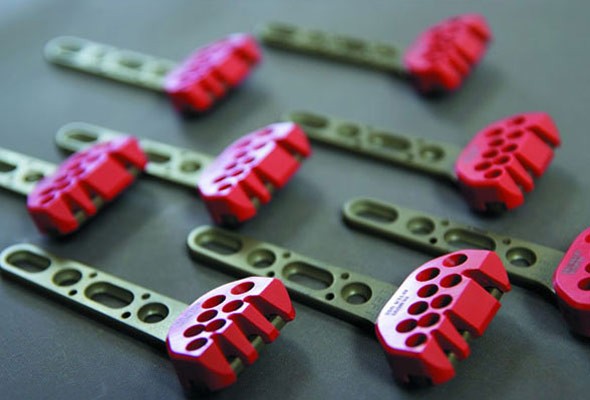

One of the latest in a new range of products developed by the company is the Volar Radius Plate (VRP). As a device used in the treatment of unstable and displaced wrist (radial) fractures, the VRP’s design incorporates into one piece, a machining operation ideal for a high end multi-tasking machine tool.

At that time, the company did not posses the 5-Axis machining capability required for this kind of work. “When producing surgical implants there is no room for error or compromise, and the quality and accuracy of the parts we produce is paramount”, David says. So when he approached John Hart to discuss what kind of machine would best suit the company’s needs, it was clear he was looking for a high accuracy multi axis machine that could produce a quality part time and time again.

After weighing up their options and considering several other brand machines, David and Austofix chose the Mazak Variaxis 500-5X II with Mazatrol Matrix controller and hyperMILL© CAM software.

The table in the Variaxis 500-5X II can move 150 degrees in the A axis (movement in the cradle) and 360 degrees in the C axis (table rotation), thanks to the full cradle design built into the machine’s structure.

The rigid construction of the 500-5X II, together with a 22kW spindle motor provides the Variaxis with the necessary power for heavy duty cutting operations. This provides the tight tolerancing needed to maintain the level of quality of the VRP product, at which according to David, “every part must be of the highest standard achievable.”

Thanks to its new software capabilities, the Mazatrol Matrix is easier to program and safer to operate, meaning the machine operators at Austofix were able to confidently run the VRX 500-5X II shortly after installation. Within just weeks, they were manufacturing complex parts thanks also to the ease with which their designers were able to integrate the hyperMILL© software into their models.

David commented that “the training provided by John Hart’s engineers was essential to allowing us develop and start production of the VRP.” He went on to say that “due to the market requirements of this product, we had no time to waste and the training given was effective, quick and easily ensured our operators could meet the project requirements on time.” In any competitive market, this kind of turn around is vital to a new product’s success.

As a customer, the most important factors influencing a machine purchase include issues of quality, cycle times, return on investment, the speed of delivery and installation, the level of service and support provided and most important of all these days, cost.

John Hart and Mazak were able to provide Austofix with the ideal solution to suit their expanding manufacturing needs and David Entwistle claims that “the machine easily met our expectations due to the accuracy it is able to hold, the cycle times it can achieve, the ease of programming and operation and John Hart’s outstanding service.”

Having listed the company on the Australian Stock Exchange in February 2008, Austofix celebrated another significant milestone in the company’s history in June 2008, with the manufacture and sale of their 100,000th product. John Hart are proud to have been able to support Austofix in their development of one of these essential products and look forward to working with David and the company in the future, to continue to grow their capabilities and product lines in house, with even more innovative and home grown technology.