Open Mind Technologies AG is set to exhibit its NC code-based hyperMILL Virtual Machining Center machine simulation for the first time at this year’s EMO. Live machining demonstrations using the innovative strategies provided by the hyperMILL MAXX Machining performance package will be performed on Stand A08 in Hall 25. The developer of CAM/CAD software and post-processors will also offer a first glimpse of its upcoming hyperMILL version 2018.1 at the trade fair, which will take place in Hanover, Germany.

Milling tasks that use powerful 5-axis machining centres are becoming more diverse, making a reliable machine simulation more important than ever before. With its hyperMILL® VIRTUAL Machining Center, OPEN MIND has developed a solution that uses the NC code after the postprocessor run, as the basis for the simulation. This ensures that the virtual machine movements correspond exactly to the real machine movements.

Maximum efficiency with hyperMILL MAXX Machining

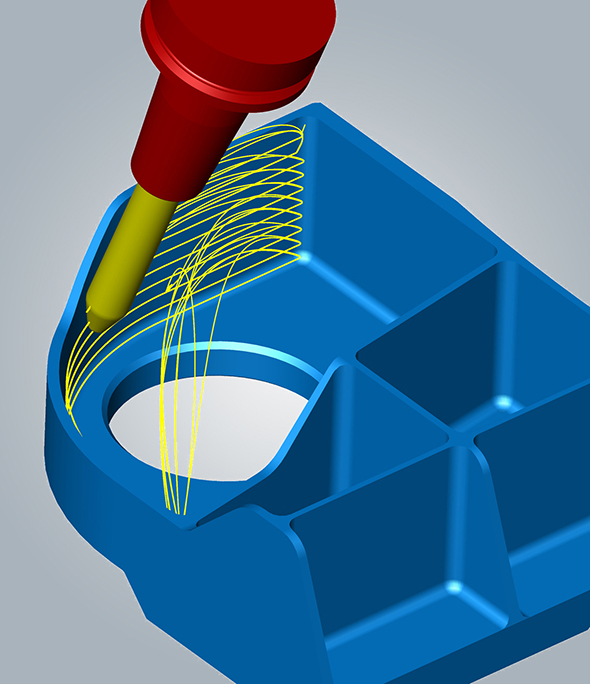

The hyperMILL® MAXX Machining performance package with its three highly efficient modules for roughing, finishing and drilling promises a major boost in efficiency. Manufacturers that use these innovative CAM strategies will be able to achieve time savings of up to 90 percent during finishing and time savings of up to 75 percent during roughing. Visitors to the show will be able to attend the live machining demonstrations taking place on the OPEN MIND stand and experience first-hand, the enormous potential for savings that can be achieved, especially with the 5-axis tangent plane machining strategy.

What to look forward to with hyperMILL 2018.1

2D contour milling on the 3D model strategy will make it much easier to program vertical surfaces. The milling contour is generated automatically by selecting the perpendicular surfaces. hyperMILL® 2018.1 will also offer Autodesk Inventor users new functions for 5-axis swarf cutting with one curve. Users can create perfect surfaces and curves for swarf cutting quickly and easily using a simple surface selection that is based on the selected geometries.

Highly efficient machining of planes and free-form surfaces with the 5-axis tangent plane machining strategy.