BAM GmbH, based in Weiden, Bavaria, is going all in with digital processes in an effort to further reduce costs and project times in contract manufacturing.

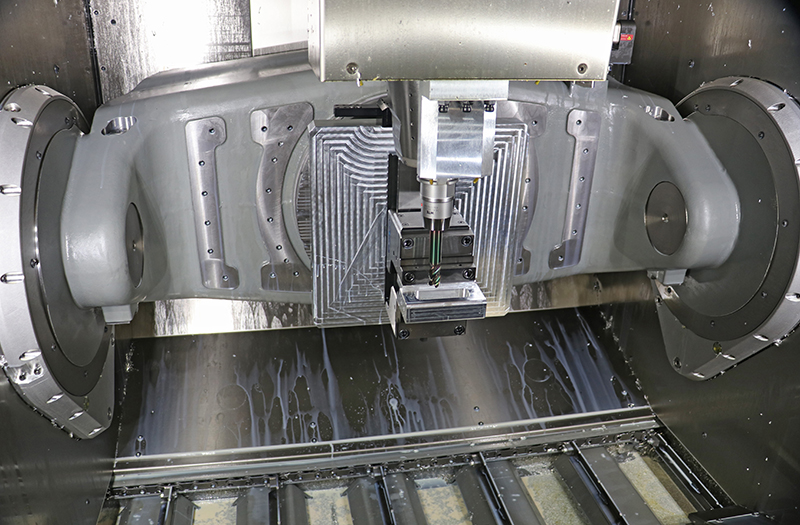

The CAM office is an essential place. Using the hyperMILL high-end CAM system from OPEN MIND, employees create NC programs based on 3D design data; in some cases, the programs are even generated fully automatically.

With the support of OPEN MIND Technologies AG, BAM has used hyperMILL AUTOMATION Center to streamline and markedly speed up CAM programming, which represents the final digital step in the transition from the customer design to the finished workpiece. Automation has helped reduce CAM programming times in hyperMILL by 70 to 80 percent.

“Thanks to the powerful 2.5D, 3D and 5-axis cycles of hyperMILL, we have succeeded in reducing setup and programming times at the machining centers, resulting in increased efficiency and higher capacity utilization,” states Stefan Bauer, Head of Manufacturing at BAM GmbH. “With its feature technology, macro databases and associated process, hyperMILL also provides a solid basis to automate programming and significantly reduce time expenditure by reusing pre-existing programming know-how.”

hyperMILL AUTOMATION Center is built on feature and macro technology, allowing any user to standardize machining steps and automatically apply them to new workpieces. OPEN MIND honed and optimized the process for use at BAM. To handle a wide variety of orders and workpieces, the CAD/CAM manufacturer integrated an interactive user guide which uses a few parameters to control automated programming.

Marco Bauer, Managing Director of BAM GmbH, is extremely satisfied with the support provided by the team of hyperMILL experts: “The competent OPEN MIND staff always provide us with expert support, even when dealing with highly complex applications and exotic projects. One of the key factors for us was that OPEN MIND develops their software in-house. As a result, we were able to obtain customized functions for our automation projects very rapidly, which has helped us improve leaps and bounds.

hyperMILL CAM system generates suitable NC programs in some cases even fully automatically

Standardize, automate and optimize your processes with the hyperMILL Automation Center.

BAM was able to save up to 80 percent time in CAM programming and further increase process reliability thanks to the hyperMILL automation solution.