The right type of automation delivers substantial benefits for manufacturers. The ability to increase spindle utilization and boost output of both people and CNC machine tools are the most obvious benefits. Additional benefits include improved part accuracy and consistency, reductions in human error and the potential for lights out production.

Any successful automation initiative begins with setting specific objectives, planning and designating a project leader. When it comes to implementing automation there are several possible objectives. These could be to reduce changeover times, economise storage space and reduce human error; maximise efficiency without increasing manpower; increase production capabilities through unmanned operations; and to enable one operator to simultaneously manage multiple machines.

When it comes to planning for CNC machine tool automation, here are some factors you should consider:

Preparedness: Ideally, machine shops should plan for automation at the time of a CNC machine tool acquisition. Machines equipped and configured for automation can save time and the cost of retrofitting after the fact. Such automation preparedness can include automatic doors, built-in robot interfaces and any other necessary options such as larger tooling capacities and special workholding systems. Or, if future automation needs are uncertain, shops can opt for CNC machines that make adding automation as easy and inexpensive as possible.

Workpieces: As a key factor in the automation process, shops must first evaluate workpiece weight and variation and job batch/lot sizes to determine ideal jobs to automate. For instance, jobs that involve small batch sizes of very different part numbers are inefficient and costly in terms of automation. Conversely, high-volume-per-year jobs produced in low-to-medium-volume re-occurring batches at scheduled intervals are ideal candidates for automation, especially when there is little variation in terms of part size, processes and features. Such jobs require fewer job changeovers and have workflows that permit automated cells to run and produce as long as possible between necessary job changeovers.

Automating for large workpieces requires careful consideration as to how those parts will be presented when loaded and unloaded from a machine tool. Shops must also determine what type of end of arm tooling will be most efficient for the larger parts.

Simple fixturing can eliminate having to maneuver big parts into complex setups. In these types of production scenarios, shops should avoid multiple sequencing where parts are clamped and unclamped numerous times during processing.

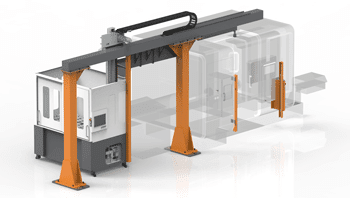

To maximise automation utilisation and help justify its cost also requires careful consideration of how machining cycle times effect up and downstream processes. For instance, when machining large parts with longer machining times, shops can integrate a robot to perform other tasks within peripheral

processes while parts are being machined. This may require the robot to ride on rails or travel overhead to serve those other processes and pieces of equipment, or be positioned to tend several of the same types of machine tools running similar parts.

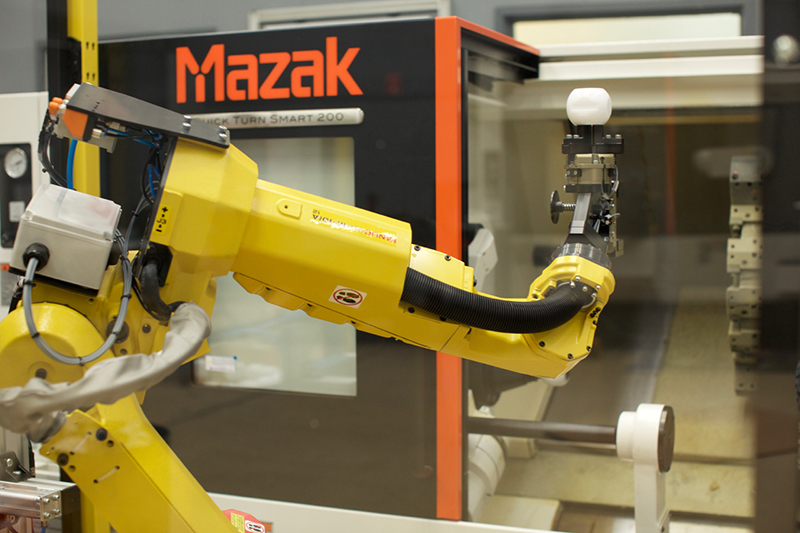

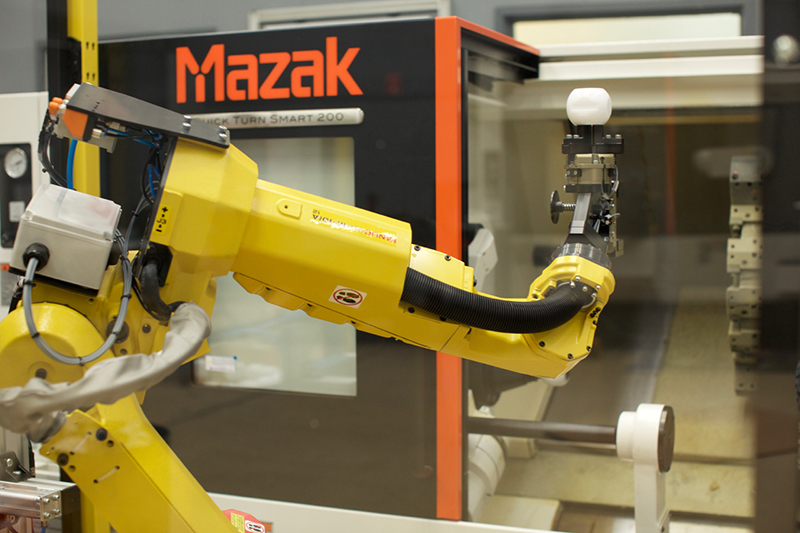

Workholding: There are many workholding situations to consider when planning automation. The physical positioning of the workpiece on the queue table or infeed conveyor prior to loading or during the loading process are common functions automated to increase speed and accuracy. If the workpiece requires positioning in the chuck or fixture in a particular attitude or needs to be aligned in the secondary operation based on features created in the first operation, vision systems or touch probes may be required to complete the task. Workholding solutions must also be designed to allow for proper clearance between end-of arm tooling and clamps when loading and unloading.

Gauging: If an unautomated process requires the operator to measure the workpiece during or after machining, automating the gauging process should be considered. There are several in-process or post-process options including touch probes, periodic artifact calibration or even use of a post-process gauge or coordinate measuring machine.

Cycle times: When considering whether or not to automate a process, cycle times will determine the capacity/size of the infeed/outfeed for finished work pieces. Cycle times will also be key in sequencing coordination of additional tasks required of the robot/automation such as loading to gages, coordinating measuring machines, wash stations, turn over stations or simply managing/arranging incoming and outgoing materials on pallets.

Unattended process: Machine shops seeking to run unattended or lights out must ensure machine reservoirs for grease/oil lubrication and coolants are of sufficient capacity to last the duration of the unattended cycle. Likewise, chip evacuations and capacity to contain chips must be large enough to eliminate the need for human intervention throughout the entire unattended cycle.

Another important precaution is to set spindle and axis overload detection to force the machine into an e-stop mode or alarm state to avoid potential for catastrophic results such as damage to the machine or scrap of expensive material or workpieces.

Tooling: Unattended automated processes necessitate excellent tool life management including predictive tool life and often redundant tooling. This is particularly true when machining hard materials such as hi-temp alloys or hardened steels.

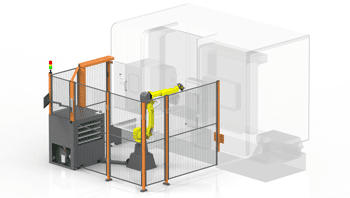

Machine shops have many automation options to achieve their goals. Solutions range from pre-engineered to customized systems that are scalable in size, cost and capability. Pre-Engineered solutions cover a broad range of process requirements and can enable a machine shop to quickly increase productivity and improve the bottom line. Such systems include bar feeders, gantry loaders and multiple pallet systems. While on the other hand, shops with more sophisticated needs such as

smaller and more varied job lot sizes, automation of multiple machines, part transfers to peripheral operations, and the handling of large, heavy or cumbersome parts can benefit from the easy to use, flexible and efficient machine loading solutions from Agile Robotic Systems.

Agile Robotic Systems is part of the John Hart group of companies. Founded on the principle of providing manufacturers with market leading technologies and first class support, we are able to draw upon a heritage of over 70 years in machine tools, and over 30 years in automation and robotics.

Agile Robotic Systems are machine loading systems for CNC machines offering unrivalled ease of use, flexibility and efficiency.