This version of Open Mind’s CAM/CAD suite hyperMILL includes a host of optimisations, machining strategies and intuitive features that can further exploit the possibilities of modern CNC machines whilst enhancing ease of use.

There are five outstanding highlights in this package that include new functions for 2D and 5axis machining. These features can considerably reduce programming times and enable efficient machining whilst numerous powerful extensions in hyperCAD-S, the CAD system for CAM users will deliver real added value.

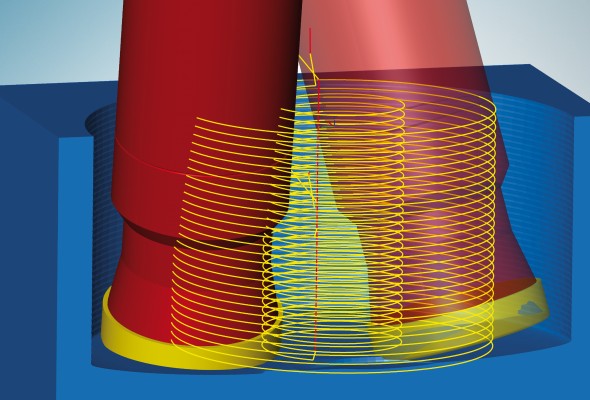

The most important expansion in hyperMILL 2015.1 is a 5axis helical drilling strategy. This helical drilling cycle generates helical tool paths with the tool plunging into the material quickly. This eliminates the need for pre-drilling operations. By setting the milling tool inclination based on 5-axes, the user can benefit from efficient and tool-friendly machining with rapid swarf removal. Particularly suited to difficult to cut materials, this strategy improves cycle times and tool life considerably.

Internal process measuring

With internal process quality control becoming increasingly important, there are three new probing cycles featured in hyperMILL 2015.1. These include the measurement of rectangle and circle elements as well as measuring parallel to the axis. The touch probe is easy to program in all cycles, just like a tool in hyperMILL. Enabling users to choose between three measuring functions, the Informative Process Control, Active Process Control and Zero-Point Definition, Open Mind will drastically improve process reliability for customers. With the ‘Informative Process Control’ feature, it is possible to create measuring data for the individual component geometries and access it from the controller, a major plus for any machine shop.

The ‘Active Process Control’ feature allows probing cycles to be integrated into the machining process in order to actively control parameters. Deviations in dimensional accuracy can be processed in the controller for actual machining based on the off-set value. This exceptional benefit is complemented by the new ‘Zero-Point Definition’ tool. This new addition makes it possible to quickly and reliably define the component zero-point, providing more precise and efficient machining. In addition to this, all movements are checked for collisions on both 3 and 5-axis machine tools.

CAD for CAM users

hyperCAD-S, the CAD element within the hyperMILL suite is also unveiling new innovations. Toolbars can be individually customised and the desired commands can be pasted into or deleted from the toolbars via a drag and drop facility. This enables the programmer to personalise the system for streamlined operation and programming times. Another new feature is the improved clipping plane. The clipping plane function is used to generate a planar section through a component. The selected clipping plane remains active within other functions, but does not affect the existing geometry of the component. This function makes it easier to analyse components whilst tool and tool paths remain unaffected.

Another hyperCAD-S highlight is the ‘Print box’ function. This is a powerful tool for creating manufacturing plans. Users can compile or print out individual views as well as clipping planes and areas to create manufacturing documentation. Component dimensions and text information are automatically adopted into the view and can be moved, hidden or shown there. All these functions have been developed to make hyperMILL work even faster and smarter for the end user.