The one stop shop for collaborative robot applications

OnRobot products open new possibilities for automating tasks that you never thought possible. OnRobot's cutting edge gripping and sensing systems for industrial automation let you easily design truly collaborative applications that enable your workforce to work side-by-side with collaborative robots on assembly, surface finishing, pick and place, machine tending or testing.

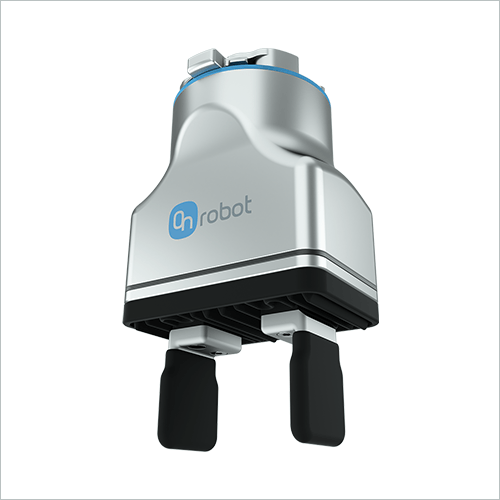

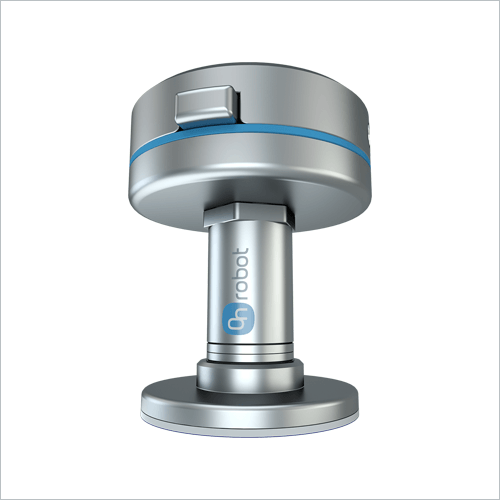

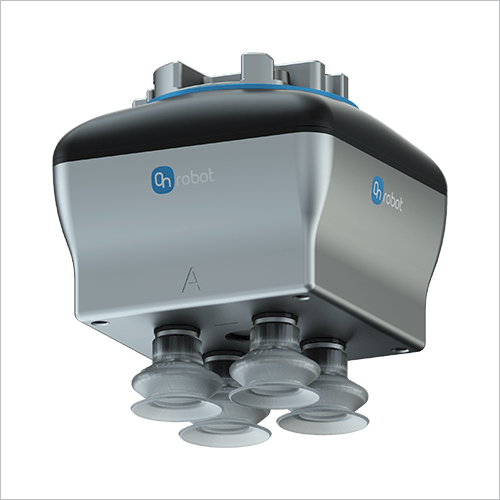

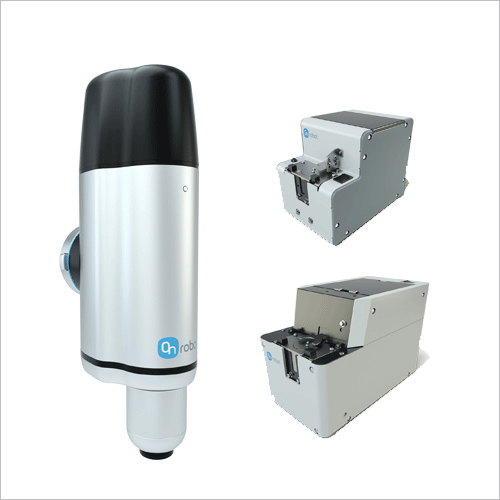

Robotic arm grippers, sensors and tool changers for your factory automation needs

Maximize your automation efforts with OnRobot’s flexible plug-and-produce tools. We offer a full range of state-of-the-art robotic arm grippers, sensors and tool changers for industrial automation. All our products work with any collaborative or light industrial robot arm.

OnRobot’s innovative grippers, force/torque sensors and tool changers are game changers within collaborative automation, opening up new automation and optimization possibilities never seen before.

Each of OnRobot’s products also come with a built-in electronic quick changer that helps make programming and installation simple and easy. OnRobot’s solutions are instantly deployable, so you can get your production up and running in no time, allowing your investment to earn itself back from day one.

Compatible with every robot brand

All OnRobot’s grippers, force/torque sensors and tool changers are compatible with robots from Doosan, TM Robot, Yaskawa, Universal Robots, KUKA, Fanuc, Kawasaki Robotics, Hanwha, Nachi, Denso, ABB and Kassow. Because OnRobot’s products are compatible with the major robot brands, you can easily get started with maximizing utilization of your robots. If your robot is from another brand, that doesn’t mean our grippers won’t be compatible with it. Contact us to discuss which solution seems most feasible for you.

OnRobot’s robot arm grippers add intelligence to collaborative processes

Collaborative robots, also known as “cobots”, and light industrial robots are widespread today because of the rise of versatile tools, such as robot arm grippers, sensors, and quick changers. By combining your robot with the right end effector, you empower its ability to handle complex processes in safe collaboration with human employees.

Collaborative technologies are known for bringing business benefits to small and medium companies, including:

![]()

REDUCED DEPLOYMENT TIME

Collaborative robots and end effectors are designed with easy programming in mind, so even employees without technical experience can learn how to use and adapt the robot in little to no time. This flexibility grants manufacturers the freedom and flexibility to experiment with applications in preparation for potential new needs

![]()

FLEXIBLE PRODUCTION

Having to fabricate unique tools for specific manufacturing tasks is a costly and disadvantageous affair. In contrast, EoAT can be easily deployed to handle different tasks and processes and seamlessly integrated into different production environments

![]()

HIGHER ROI

Flexible end effectors allow robots to complete repetitive tasks with more consistency and precision than human workers, leading to faster ROI for manufacturers. While the robots handle the dull, dirty and dangerous tasks, the employees can take on higher-level tasks better suited for a human mind

Grow your business with new technology

OnRobot’s smart solutions enable robots to handle adaptive, high-precision applications that have been too complex to automate – until now.