2024 has arrived and economic factors continue to challenge manufacturers.

The manufacturing sector will continue to experience a mild recession as the consumer-driven part of the economy slows. Labour shortages will also persist and on top of it all, wages will climb along with interest rates and energy costs.

The new year also brings new opportunities in manufacturing. Foreign investment, reshoring activity and vertical expansion within certain market segments are and will continue to keep recession in check.

Faced with today’s challenges and opportunities manufacturers must ask themselves a critical question:

How can we remain competitive?

The answer: Advanced manufacturing technology.

2024 is the year manufacturers need to prepare for the expected upswing in 2025, and continue to invest in innovative technology that will help overcome industry challenges and help manufacturers to compete effectively.

These technologies include machine tools that provide multi-tasking capabilities as well as those that perform full simultaneous 5-axis part machining. Automation, whether simple or sophisticated, will also play a key role in the future success of manufacturing, as will digital solutions for machine tool connectivity.

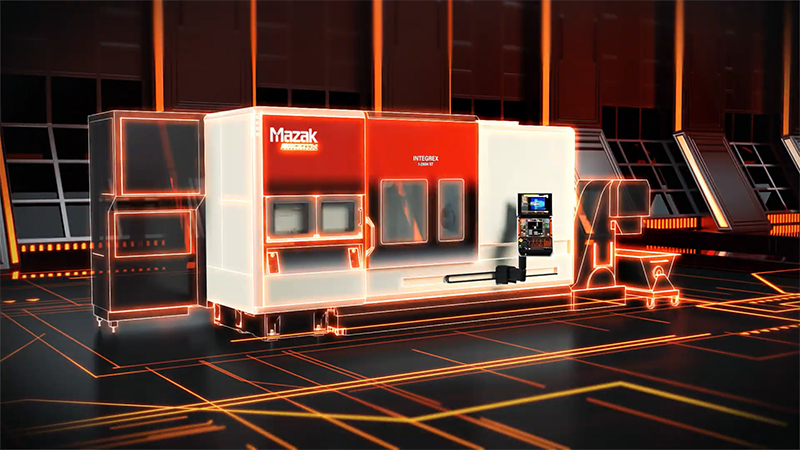

Mazak multi-tasking machines allow manufacturers to produce more parts with less capital equipment. They also significantly reduce work in progress (WIP) and maximise the output of existing labour forces while boosting overall part quality. Find out more about Mazak Integrex Multi-tasking Machines.

Taking the multi-tasking concept a step further, Mazak hybrid-type multi-tasking machines combine processes such as high-precision gear cutting into single machine platforms for even more efficient production. Take a look at the Mazak Hybrid Multi-tasking Machines.

Like multi-tasking machines, Mazak machines with full simultaneous 5-axis machining capabilities can provide complete part machining with fewer setup changes. Equipped with powerful high-speed lookahead controls, these machines give manufacturers the ability to successfully machine the most complex part designs. Find out more about Mazatrol CNC Programming Controls.

Growth in automation is at an all-time high and can entail systems from simple bar feeders, parts catchers and gantry loaders to cobots, articulated standalone robots or multi-level palletised cells. Automation gives manufacturers the ability to overcome shortages of skilled labour, increase their overall productivity and drive profitability. Find out more about Mazak Automation Systems.

Along with machine technology and automation, digital manufacturing solutions are critical to a machine shop’s success now and in the future. Effective digital connectivity is a must for safe and secure machine monitoring. Further, the data generated is crucial to process optimisation and increased machine tool utilisation. Take a look at the Mazak CNC Machine Production Support Software.