hyperMILL 2020.2 offers numerous new functions that will simplify and speed up your daily tasks.

Thanks to extensions for turning and for additive manufacturing, users can now deploy these technologies even more efficiently and reliably.

![]() Download a hyperMILL Version 2020.2 brochure2.60 MB

Download a hyperMILL Version 2020.2 brochure2.60 MB

What's new in hyperMill 2020.2?

Toolpath Mirroring

With the ‘Mirror’ function in previous versions, the toolpaths for symmetrical components were always generated and recalculated on the basis of mirrored geometry data. The new ‘Mirror Path’ function enables simple mirroring on the basis of the previously calculated toolpaths. With this method, the machining direction is mirrored as well, and climb milling becomes conventional milling. You can enable this option in the ‘Mirror Path’ settings, and it is available for all 2D, 3D, 5-axis and additive strategies.

Benefit: Shorter calculation time; improved process reliability.

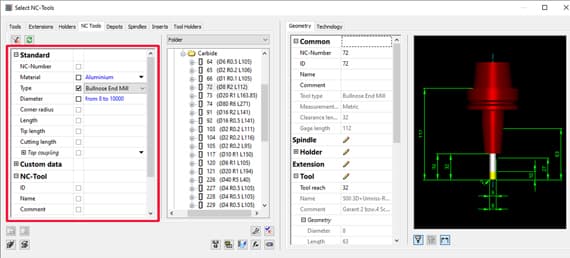

Tool Database

In the tool database, the filter properties are now integrated directly into the top level of the user interface, meaning they are always visible. Another improvement is that directly within the filter properties, you can now also enable the material from the job list, the spindle holder from the machine properties, and the tool preselection from the job. In addition, you can perform searches for customer-specific information.

Benefit: Faster tool search; more user-friendly.

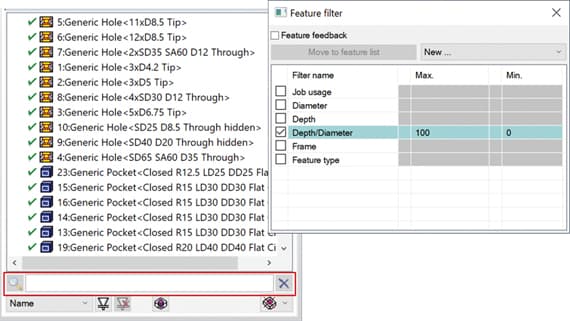

Feature Filter

Within the feature management, you can now perform text searches for specific feature properties. For example, this enables you to quickly locate specific feature types such as holes or pockets, as well as hole diameters.

Benefit: More user-friendly; saves time during programming.

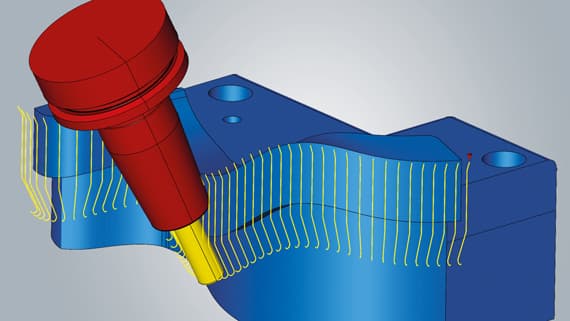

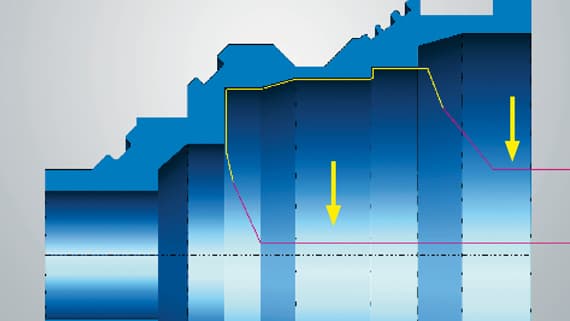

3D Cutting Edge and 5-axis Cutting Edge Plunge Milling

For the machining of cutting edges in particular, the plunge milling strategies offered by 3D and 5-axis machining represent an efficient way of removing material quickly and reliably. For this, the cutting edge is defined either via a curve or a face. You can restrict machining in the axial direction by defining a secondary curve or a distance.

With 3D machining, the material can be removed by swarf cutting or plunging. Rest material machining is easily calculated using a reference job.

With 5-axis machining, you can also include undercut areas in the plunge job, such as for cutting edge. The tool tilt is specified by the lateral inclination. In order to optimally adapt a retract movement to the component, you can specify both a distance as well as a circular or linear movement profile.

Benefit: Efficient machining of cutting edge.

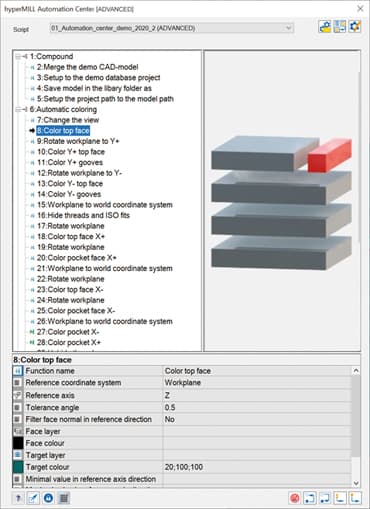

hyperMILL AUTOMATION Center

The hyperMILL AUTOMATION Center is the foundation for further automation, and serves as both a development and runtime environment. This makes it possible to standardize and automate complex process workflows in hyperCAD-S and hyperMILL. As a central software component, the hyperMILL AUTOMATION Center offers not only the automation experts at OPEN MIND comprehensive functionality for process automation; this functionality is now also available in two versions for OPEN MIND customers as well.

Basic

With 2020.2, the functions of the basic version have been extended. It is now possible to independently create small-scale automation projects for prismatic components. As well as job list creation and clamping device selection, feature recognition and macro application are now also available. This makes it possible, for example, to automate the entire process of machining an ejector plate.

Features

- Job list creation with extended stock model options and clamping device management

- Hole and pocket recognition

- Compound job creation

- Macro application including optimization of job list and sorting of job IDs

- Calculation of global clearance plane

- Calculation of all jobs

- Creation of NC program and report

Advanced

The hyperMILL AUTOMATION Center Advanced offers a level of technology that reaches far beyond the automation of standard geometry features. Here, you can define and standardize complex processes. The overall shape of the CAD models is only of secondary importance in this context. This solution primarily focuses on the individual elements that may be contained within a CAD model.

With our automation solution, nearly all of the functions from hyperMILL as well as the CAD functions from hyperCAD-S can be accessed in order to automate complex manufacturing processes. This involves defining all the individual steps for data preparation and programming, right up to simulation and NC program generation. Once a manufacturing process has been defined, it can be applied to any new components, and it can be run automatically. If there are any decisions that cannot be made with full certainty within the automation process, the user is prompted to make the relevant choices during the program run. The user is interactively guided through the individual process steps, making it possible to program the machining job in a fraction of the time.

Features

- hyperCAD-S and hyperMILL® functions can be automated

- Comprehensive template functions

- Processing of complex geometry information

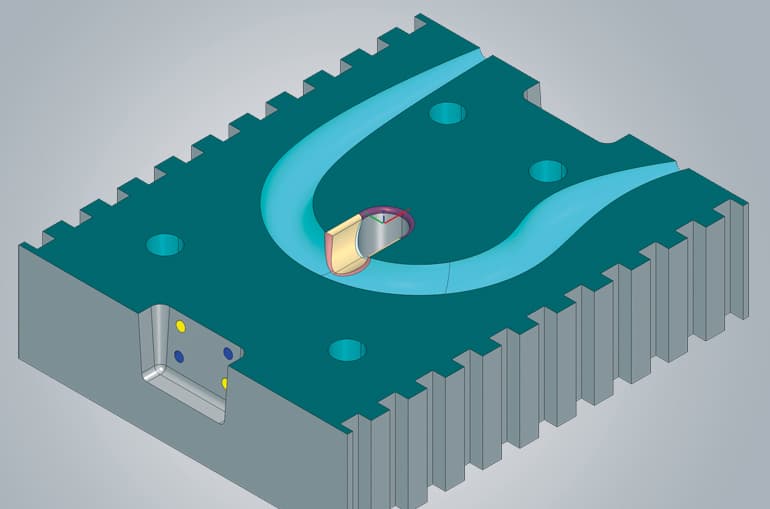

Manual Approach and Retract

There now is an extension for individually adapting approach and retract movements using drawn curves. This makes it possible for the user to control the component properties very precisely and to direct the machining process more efficiently. Note that all movements are fully collision-checked.

Benefit: More user-friendly.

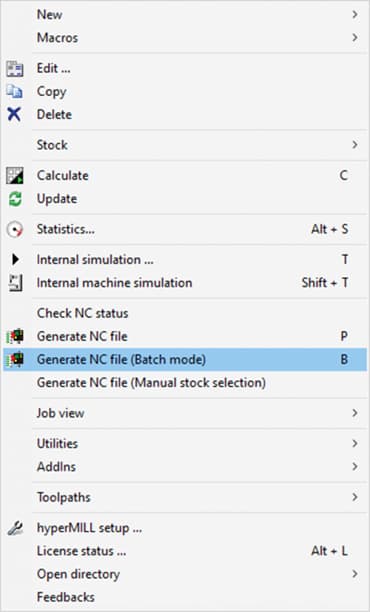

Continuous Simulation

Connectivity between hyperMILL® and the VIRTUAL Machining Center has been further improved. With the ‘Generate NC File in Batch Mode’ option, a newly-generated NC program is loaded directly into the currently active simulation application, where you can simulate and check it in the familiar manner, as well as releasing it for machining. This method significantly reduces loading times, as the machine and model data does not need to be reloaded. Particularly when multiple individual programs need to be set up for a component, this makes for a faster and more straightforward workflow.

Benefit: Faster simulating.