The Mazak NEO series has evolved into a 'Next Generation' machine, with enhanced spindles, tables, hydraulic fixtures and automation equipment.

Equipped with even more 'Excellent' specifications.

Capable of providing 'Optimal' solutions to meet customer needs.

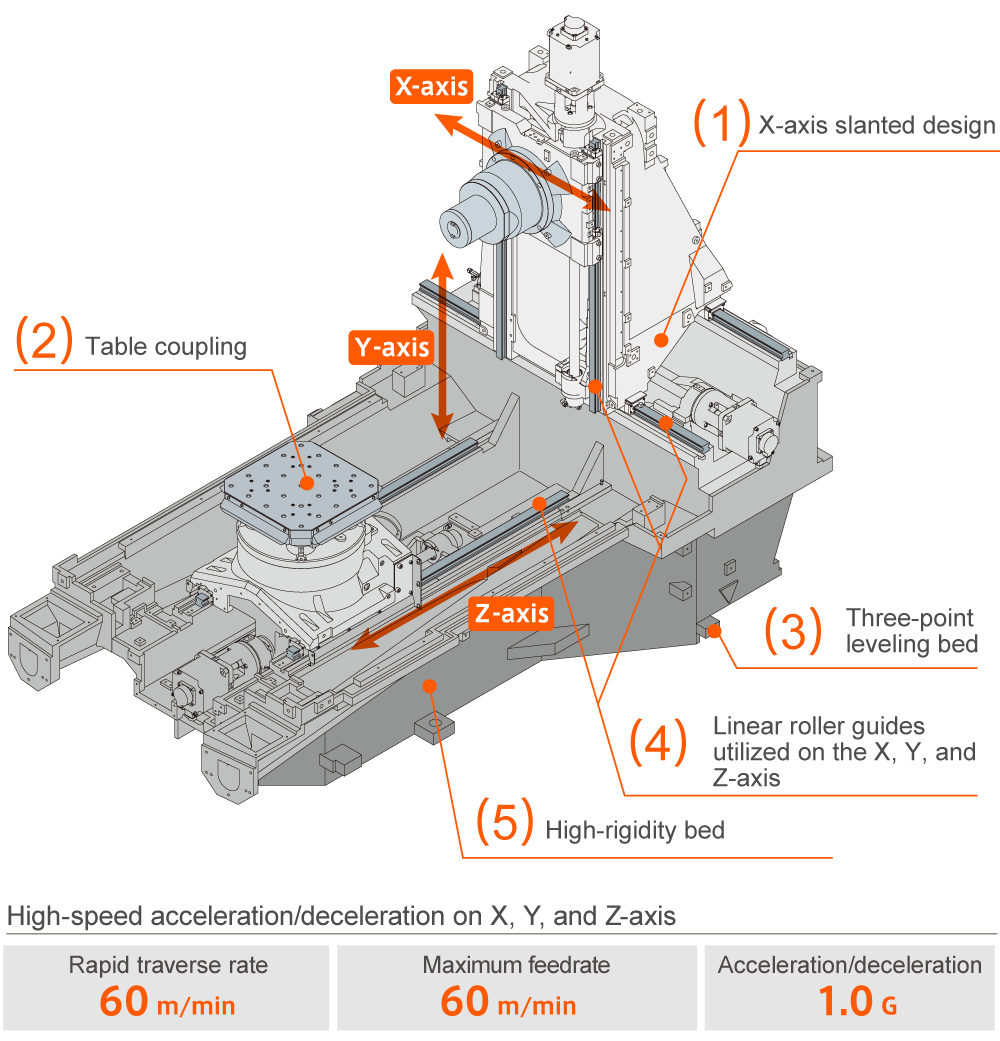

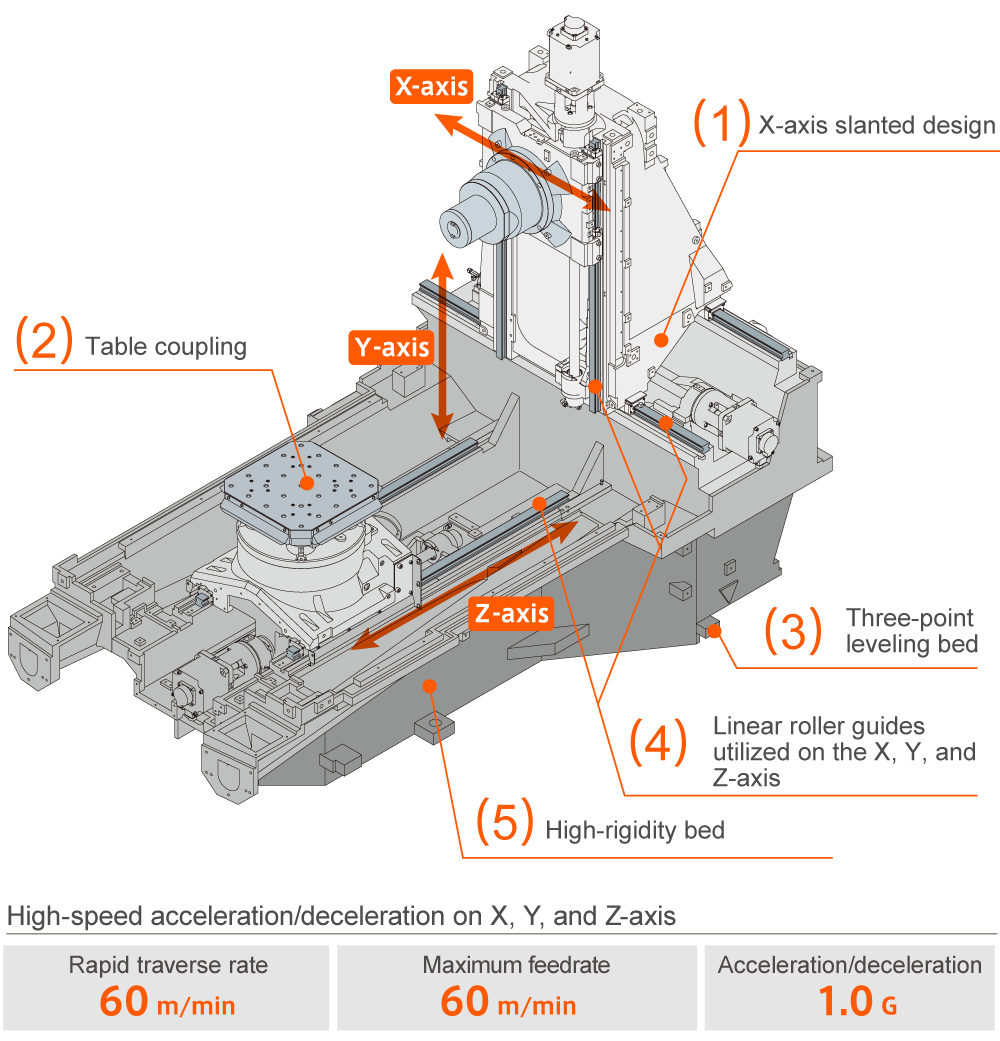

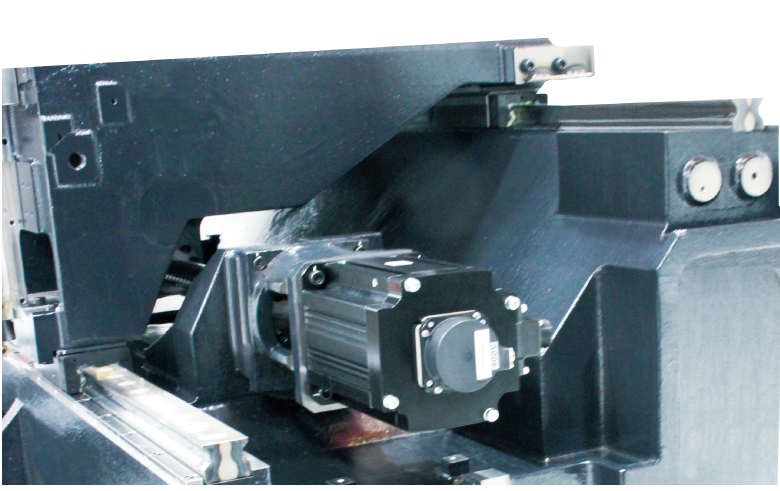

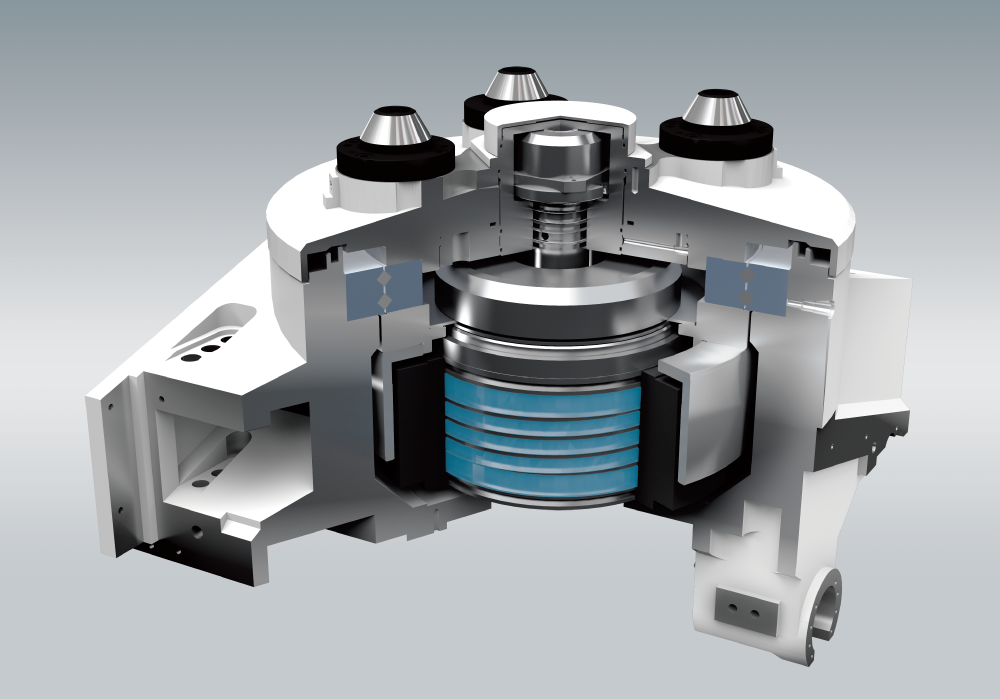

(1) X-axis slanted design

The mounting surfaces of the X-axis linear guide rails are at different heights to ensure high rigidity for high-speed and high-accuracy positioning.

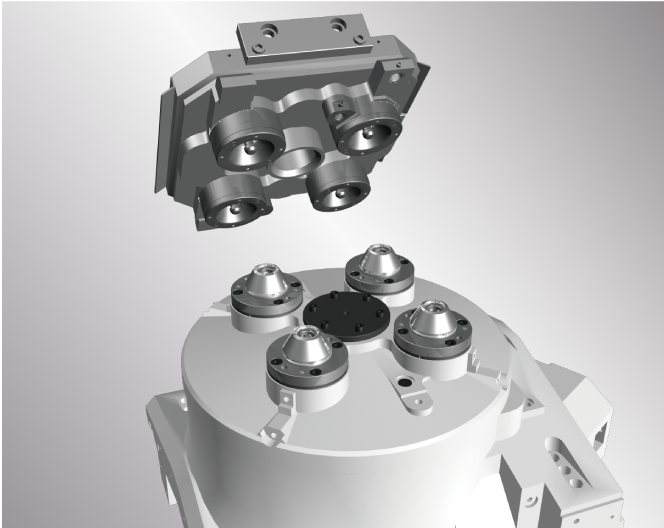

(2) Table clump

The table and pallet are clamped on 4 taper cones for stable heavy-duty machining.

(3) Three-point leveling bed

Three-point leveling bed simplifies machine installation.

(4) Linear roller guides utilized on the X, Y, and Z-axis

The HCN series uses linear roller guides on the X, Y, and Z-axis for high-accuracy and heavy-duty machining.

(5) High-rigidity bed

The high-rigidity bed is reinforced with strategically located ribs to ensure stability during X and Z-axis travel.

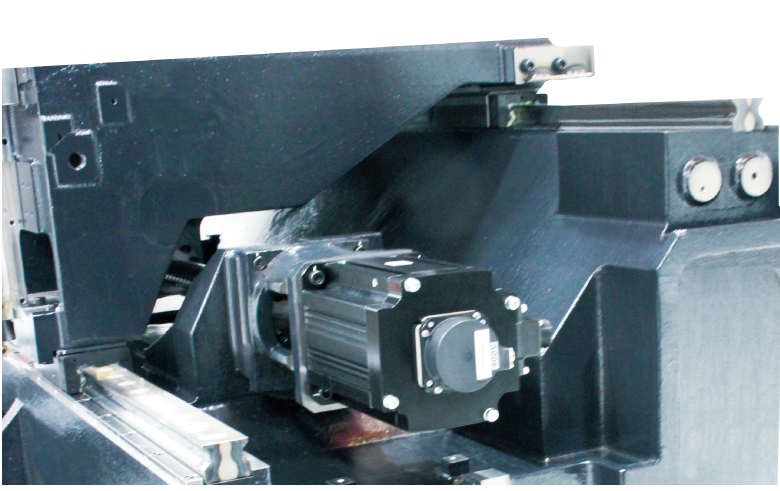

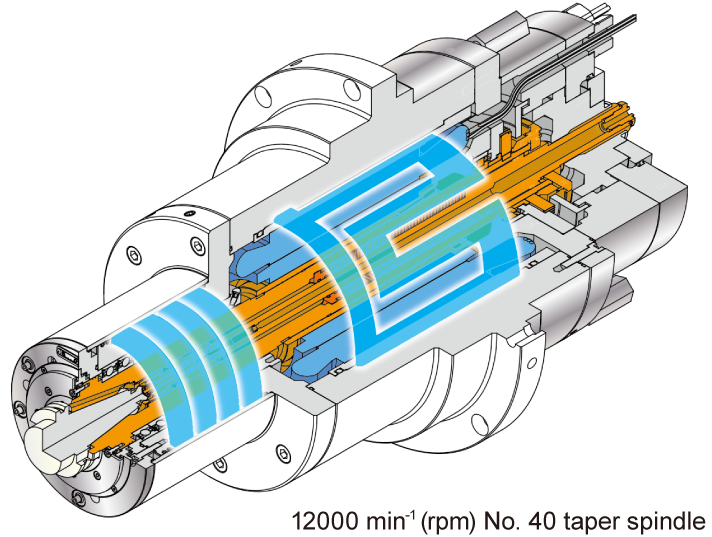

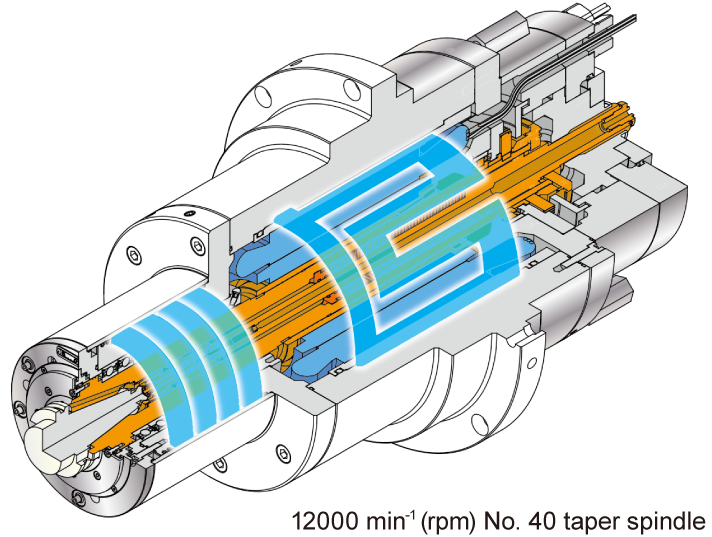

Spindle

Integral spindle/motor

The integral spindle/motor design minimizes vibration during high-speed operation to ensure exceptional surface finishes and maximize tool life.

Spindle thermal control

For high-accuracy machining, temperature-controlled cooling oil circulates around the spindle bearings and headstock to minimize any thermal change to the spindle.

Spindle variation

Standard [ 12000 min-1(rpm) ] *

No.40, BBT-40, HSK-A63

Integral spindle/motor

Grease lubrication

| Speed |

12000 min-1(rpm) |

| Output |

18.5 kW (25 HP) [40% ED] |

| 15 kW (20 HP) [cont. rating] |

| Max. torque |

81.9 N・m [40% ED] |

* Standard spindle varies depending on the region.

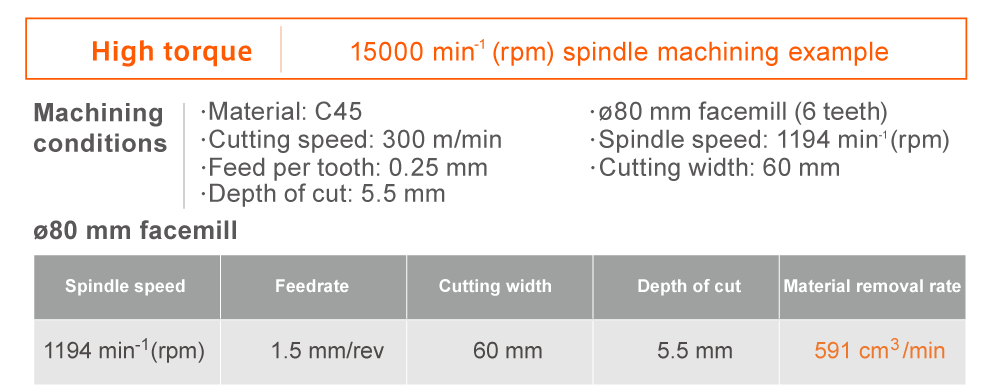

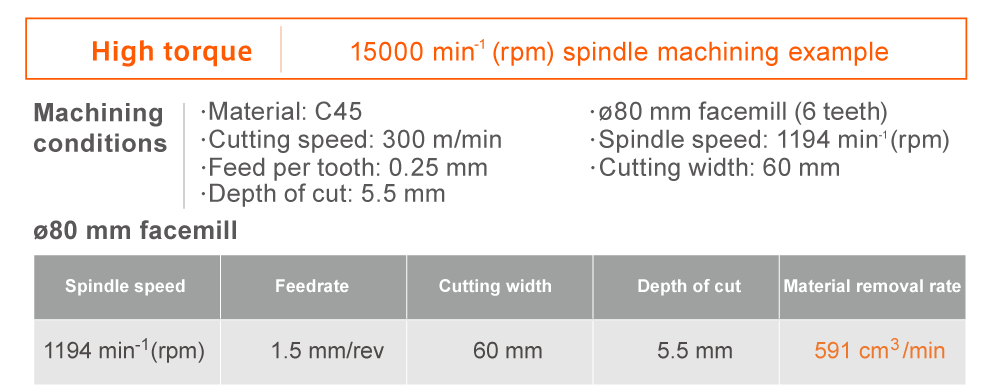

High torque [ 15000 min-1(rpm) ] (OPTION)

No.40, BBT-40, HSK-A63

Integral spindle/motor

Oil and air lubrication

| Speed |

15000 min-1(rpm) |

| Output |

46 kW (62 HP) [40% ED] |

| 37 kW (50 HP) [cont. rating] |

| Max. torque |

200 N・m [40% ED] |

High speed [ 18000 min-1(rpm) ] (OPTION)

No.40, BBT-40, HSK-A63

Integral spindle/motor

Oil and air lubrication

| Speed |

18000 min-1(rpm) |

| Output |

35 kW (47 HP) [40% ED] |

| 26 kW (35 HP) [cont. rating] |

| Max. torque |

84 N・m [40% ED] |

High speed, high output [ 20000 min-1(rpm) ] (OPTION)

No.40, BBT-40, HSK-A63

Integral spindle/motor

Oil and air lubrication

| Speed |

20000 min-1(rpm) |

| Output |

42 kW (56 HP) [40% ED] |

| 26 kW (35 HP) [cont. rating] |

| Max. torque |

161 N・m [40% ED] |

High speed [ 25000 min-1(rpm) ] (OPTION)

HSK-A63

Integral spindle/motor

Oil and air lubrication

| Speed |

25000 min-1(rpm) |

| Output |

23 kW (31 HP) [40% ED] |

| 15 kW (20 HP) [cont. rating] |

| Max. torque |

22 N・m [40% ED] |

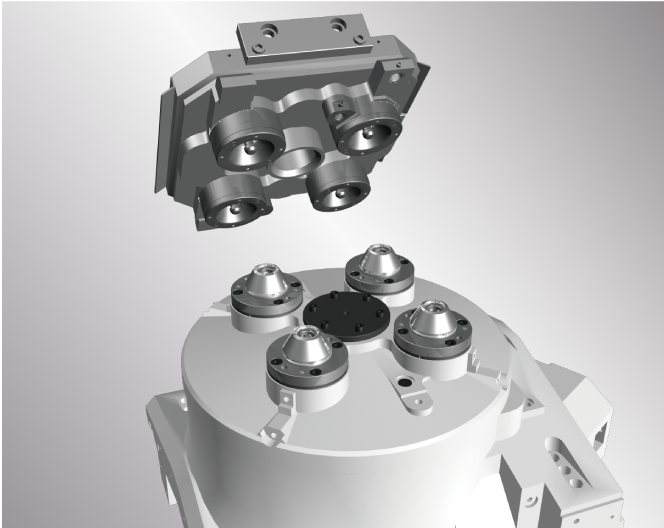

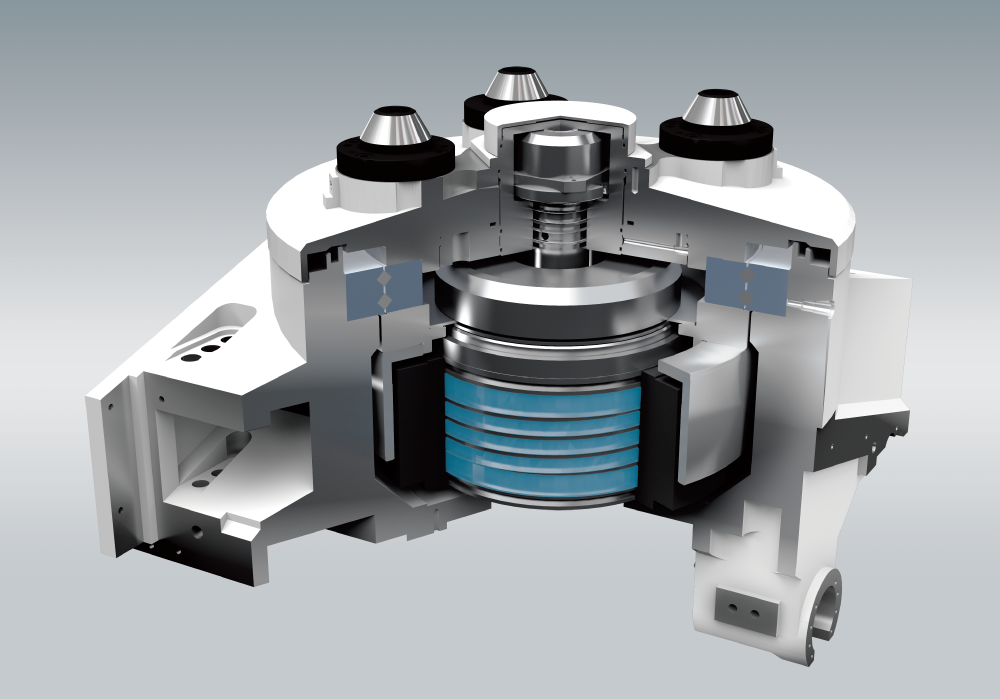

0.0001°× 3600000 NC rotary table

The NC rotary table uses a backlash-free rotary gear cam to ensure high accuracy as well as long service life.

DDM rotary table (OPTION)

For efficient high-speed operation, direct transmission of driving power to the rotary table axis eliminates power transmission components such as the worm shaft and the worm gear.

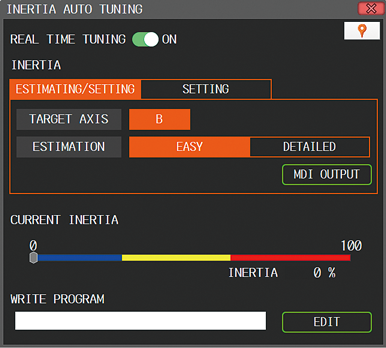

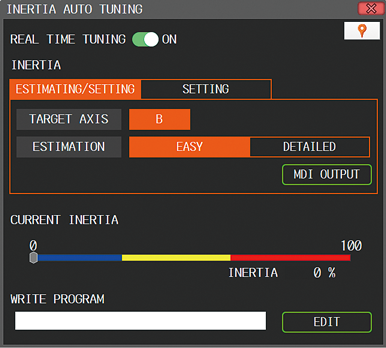

Inertia Auto Tuning

Supports inertia adjustment on the screen

- Generate estimated programs

- Visualize estimated results

- Adjust programs

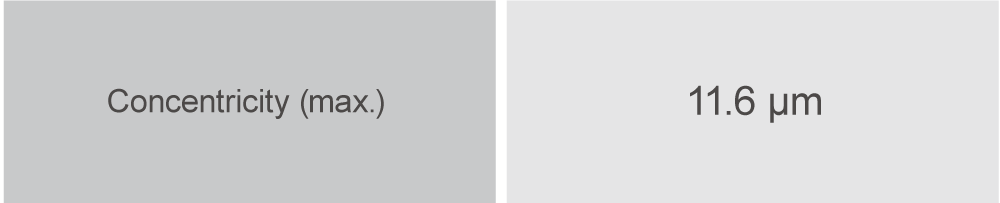

Continuous inverted boring accuracy

Test results

Perform continuous machining from a cold start for stable high accuracy. Special tools and compensation with touch sensor are not required for high-accuracy boring.

Note: The inspection is conducted on a recommended foundation with room temperature controlled to 22°C±0.5°C after machine has reached operating temperature. Example results for reference only.

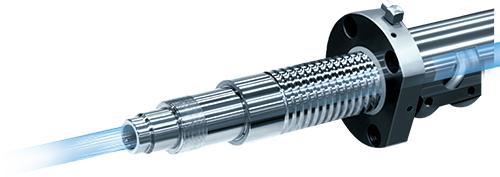

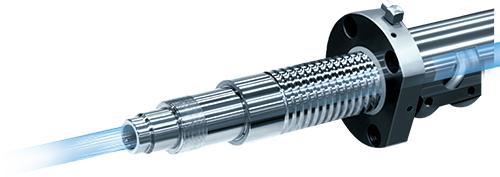

X, Y, Z-axis ball screw core cooling

Temperature-controlled cooling oil circulates through the ball screw cores to ensure stable machining accuracy over extended periods of high-speed operation.

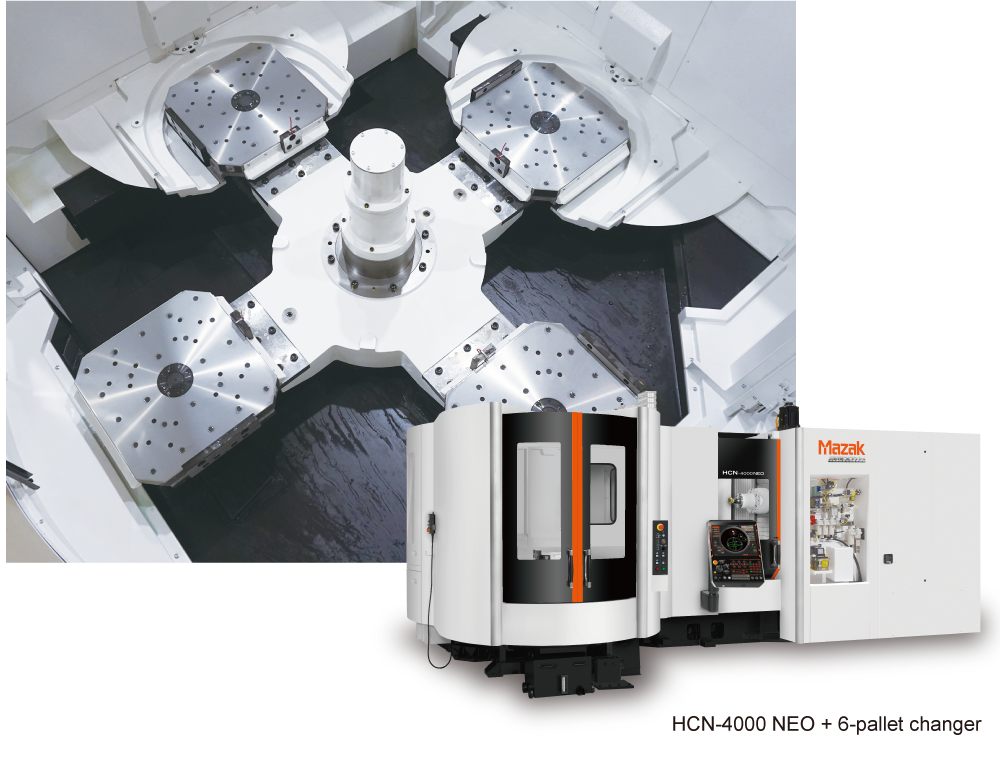

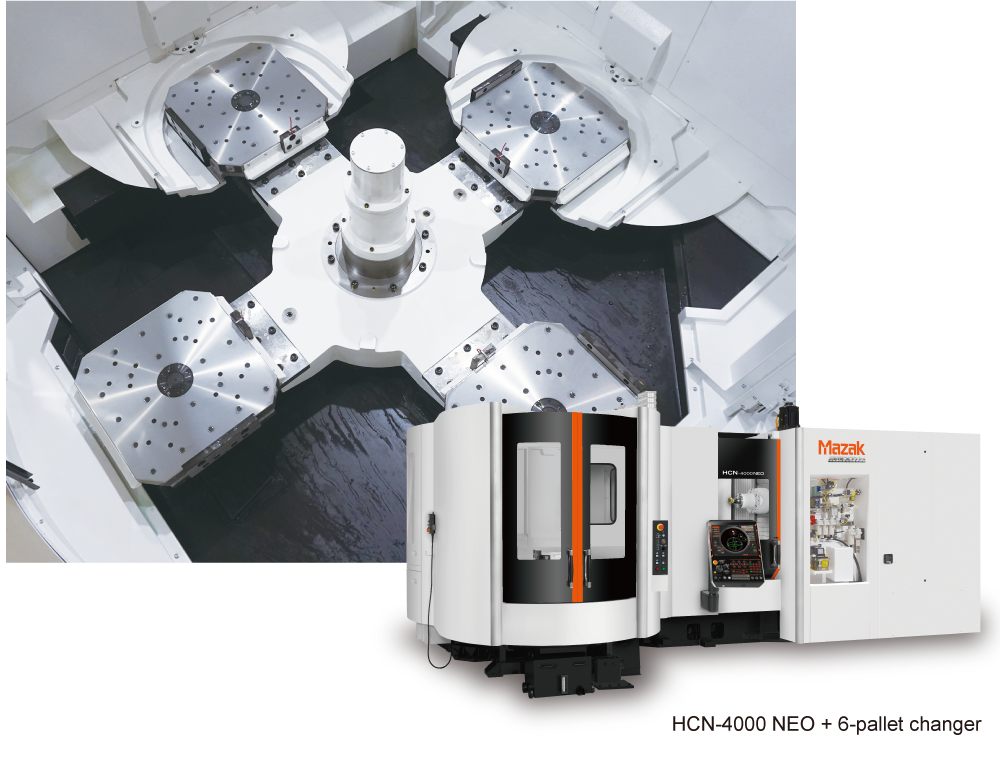

6-pallet changer (OPTION)

Set up multiple workpieces for automatic operation over extended periods of time.

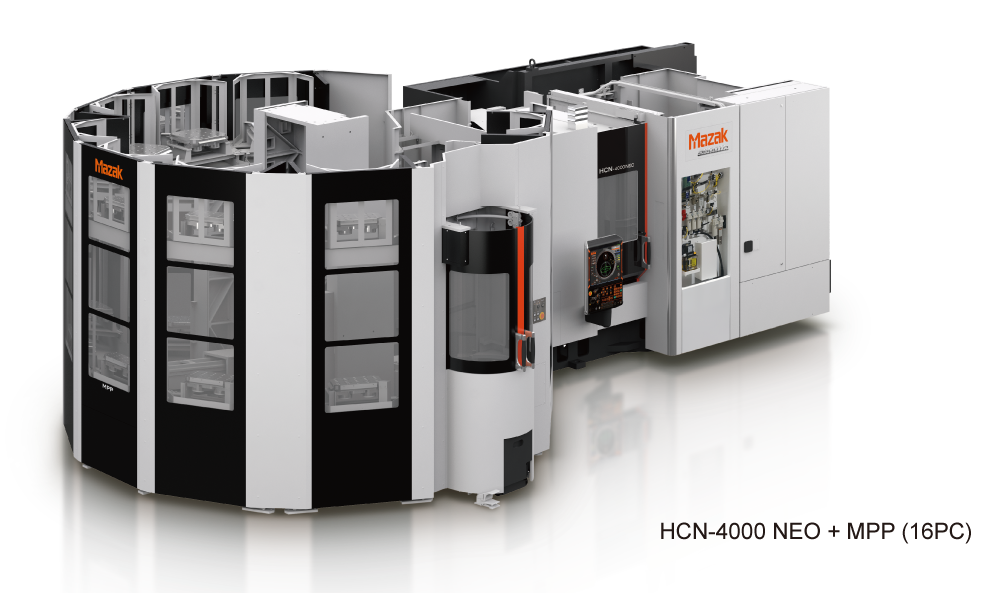

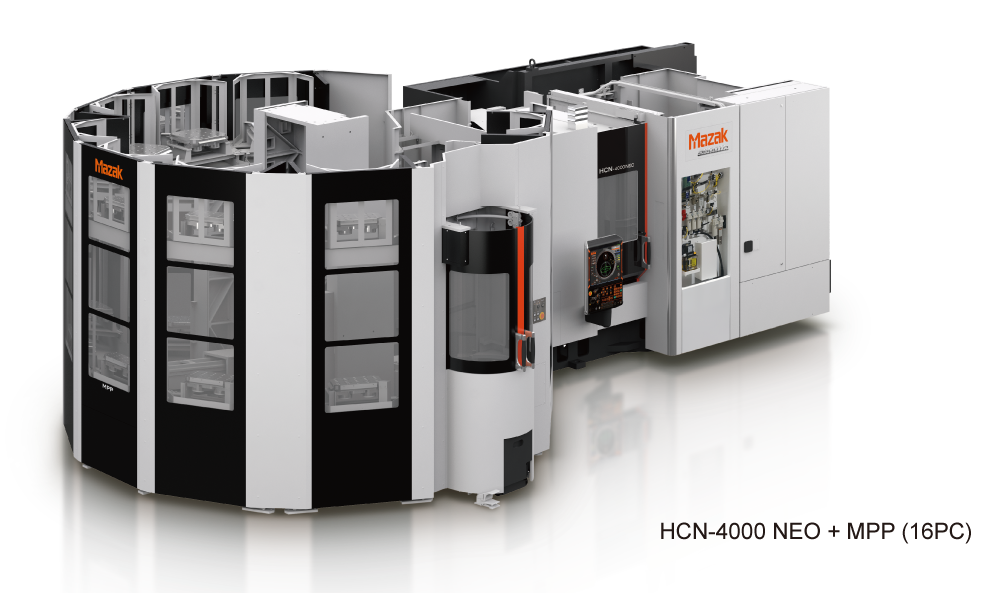

MPP (MULTI PALLET POOL) (OPTION)

Compact multi-pallet stocker system stores a maximum of 16 pallets in its pallet stocker.

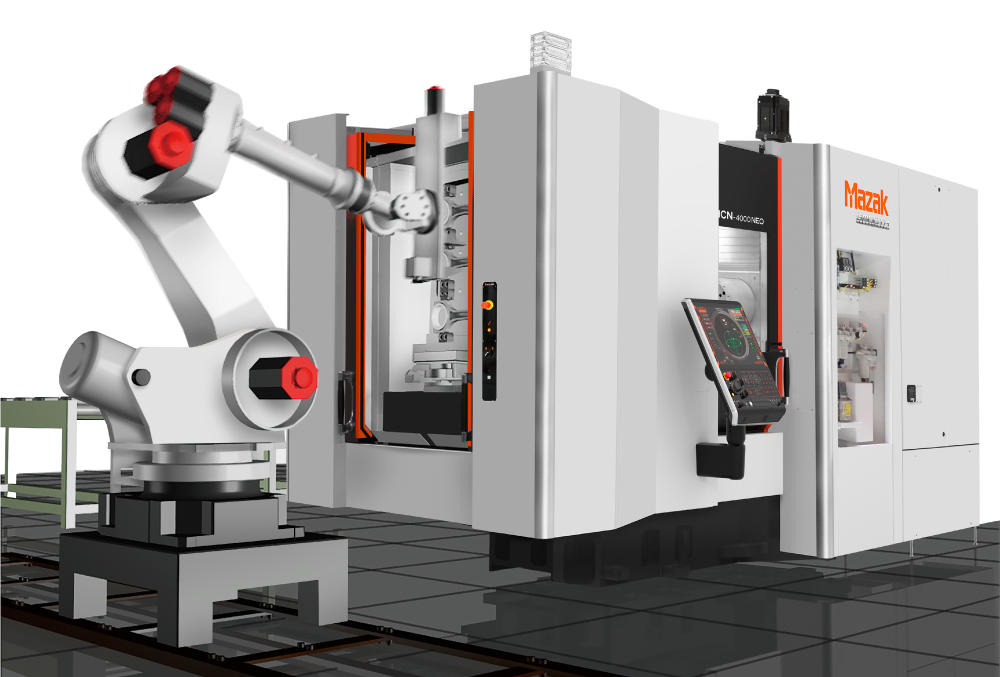

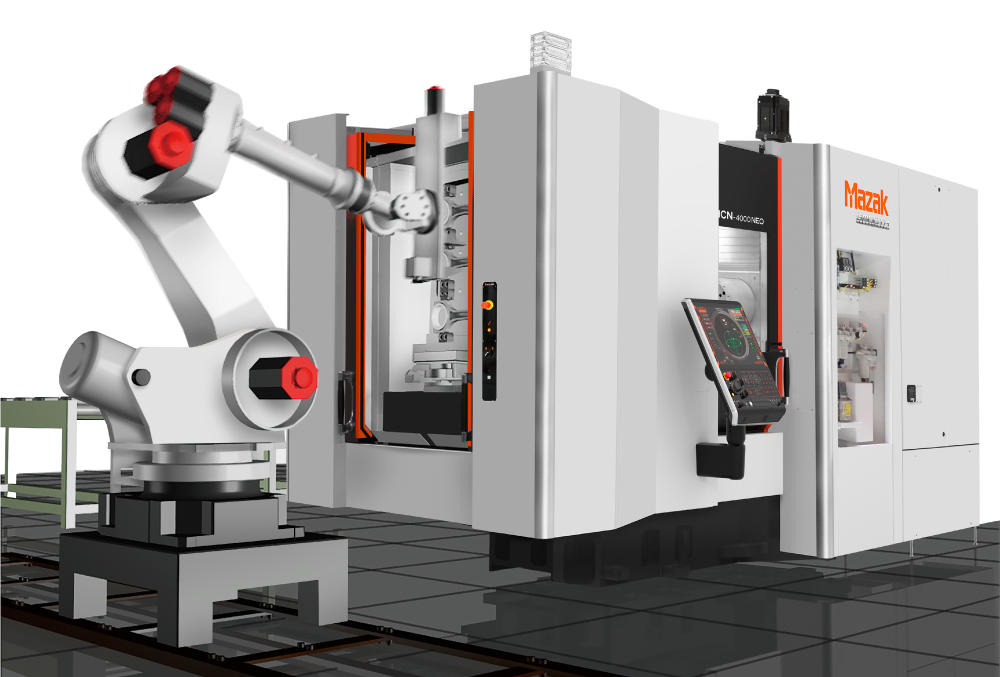

Robot system (OPTION)

Interface for connecting an external robot for workpiece loading/unloading to/from automatic hydraulic fixtures is optionally available.

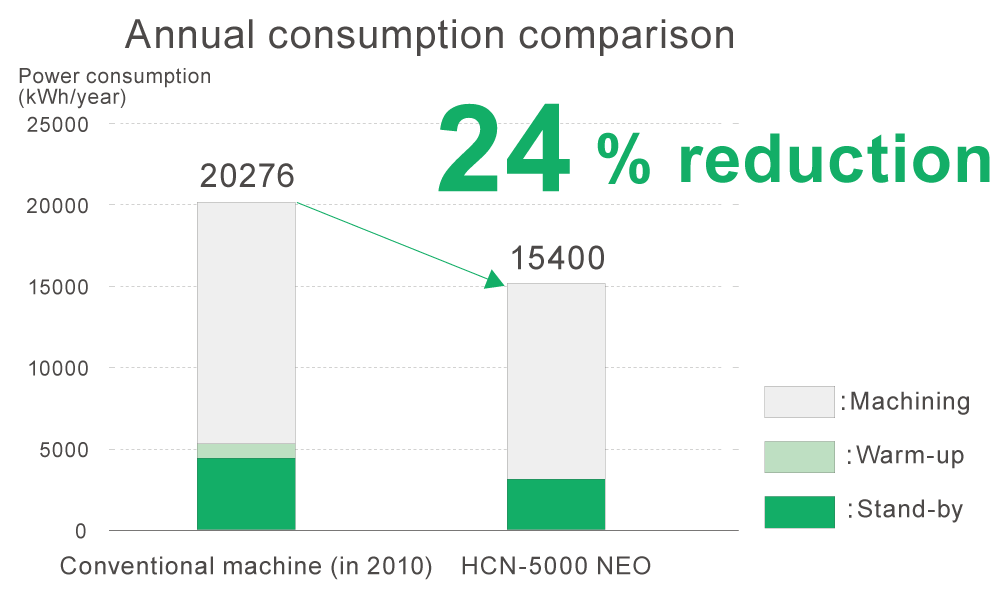

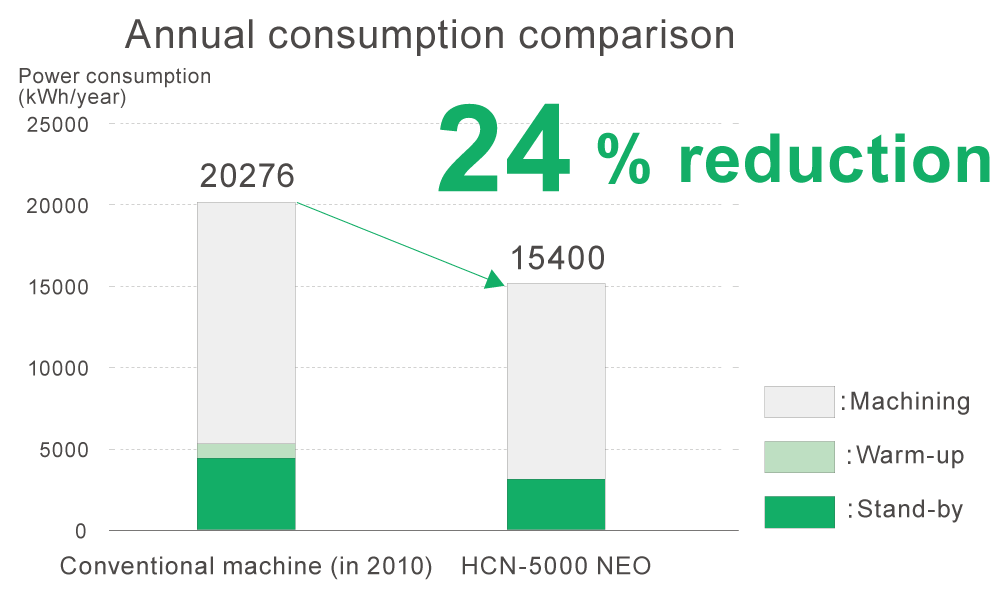

Energy-saving equipment reduces power consumption

- Hydraulic unit utilizing accumulator

- Inverter type chiller unit

- Reduced warm-up time by stable machining accuracy

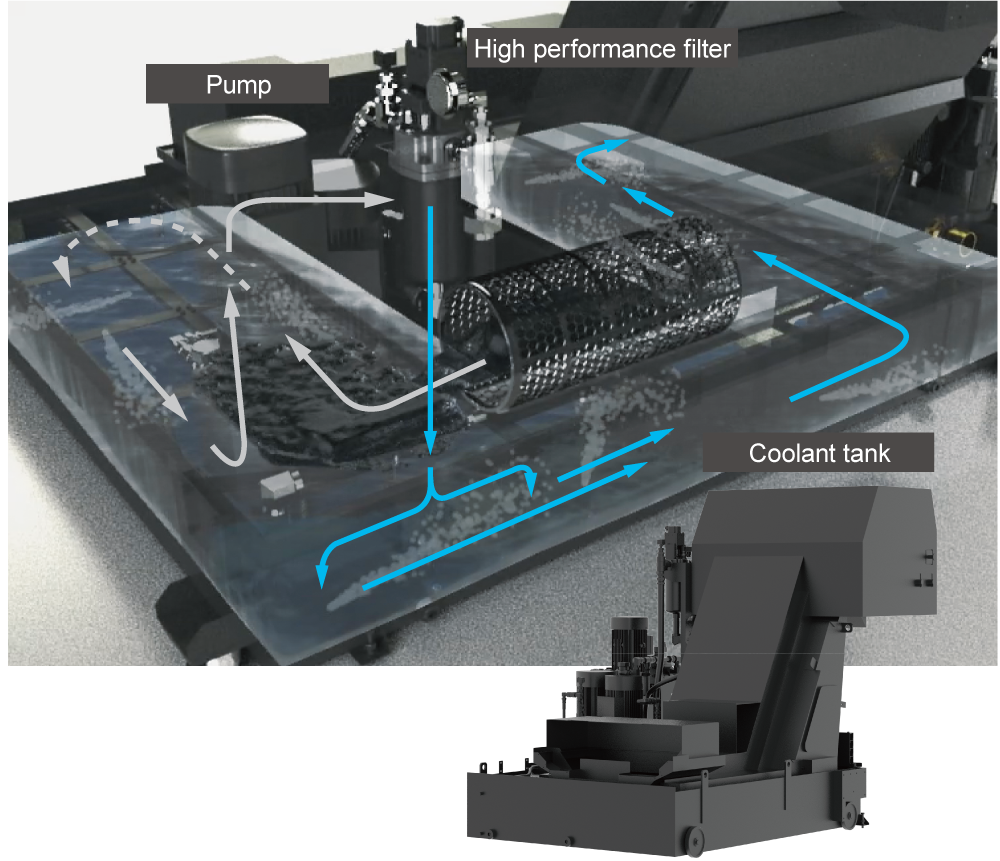

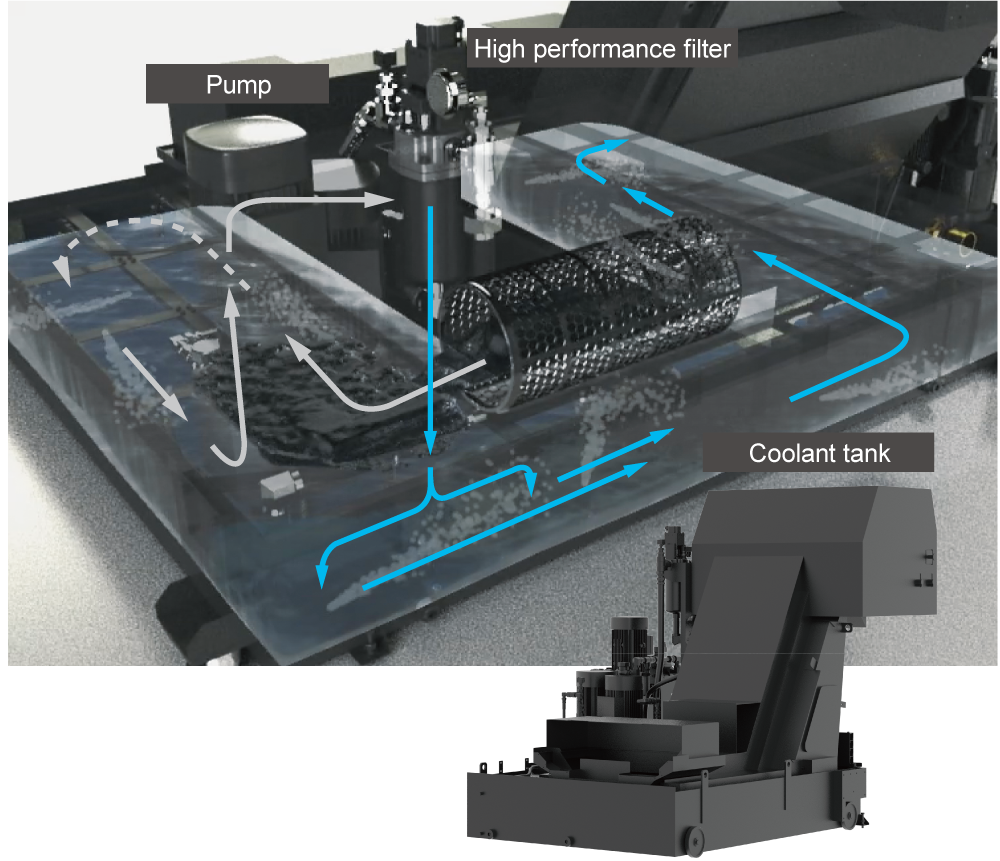

Energy-saving coolant system with sludge removal performance

No need to frequently clean the tank

The coolant tank has a coolant jet that makes a vortex in the center so that small machined chips will not settle in the tank.

Thanks to this feature, the coolant tank stays clean and the service life of the coolant is extended. Ease of maintenance is also ensured. The frequency of coolant changes is reduced as well as CO2emissions at coolant disposal.

High performance filter removes 99% of sludge

High performance filter removes 99% of sludge from the coolant.

Reduced running cost / environmental impact

Reduced tank cleaning, optimal control of coolant discharge and the efficient pump operation with inverters, reduces power consumption and CO2 emissions.