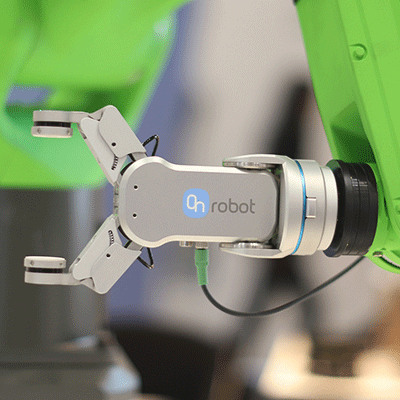

John Hart specializes in systems for robotic assembly, robotic machine tending, robotic palletizing, robotic part transfer, robotic picking and robotic packaging and we can provide a robotic automation solution that will give you the return on investment you are looking for.

A John Hart robotic automation system results in higher productivity, reliability, capability, and safety. It can significantly reduce operating costs, and under-utlization of manufacturing machines and facilities.

Our long list of experience includes robotic automation systems for automotive, aerospace, mining, pharmaceutical, food and beverage, and consumer goods industries throughout Australia, Asia and USA.

Revolutionize your manufacturing.