Mission Discovers 1st World with Two Stars.

OPEN MIND Technologies, a leading developer of CAD/CAM software solutions worldwide, has announced that Ramco Machine, LLC (Rowley, MA U.S.A) is helping to impact the future of space exploration by using hyperMILL CAM software and 5-axis machining to make parts for an advanced NASA satellite mission.

The mission, named Transiting Exoplanet Survey Satellite (TESS), is credited to discovering its first circumbinary planet - a world orbiting two stars.

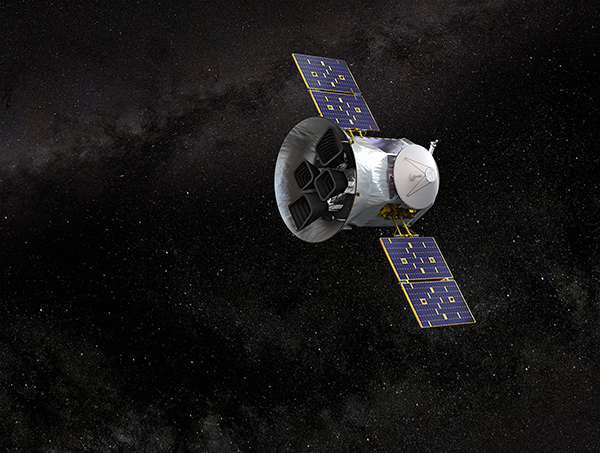

Artist concept of TESS Spacecraft. Image Courtesy of NASA's Goddard Space Flight Center.

In 2017, Ramco was contracted by MIT Lincoln Laboratory (Lincoln, MA U.S.A.) to fabricate the critical camera mount brackets for an important NASA TESS satellite mission. NASA's TESS mission is designed to explore and survey nearby bright stars to analyze planets, both smaller and larger than earth, as the planets circle their host stars and the earth orbits the sun. In 2018, a solar powered in-space satellite equipped with four ultrasensitive cameras was launched aboard a two-stage SpaceX Falcon 9 rocket on its way beyond earth's solar system to outer space. The four-camera system developed at the MIT Lincoln Laboratory monitors the brightness of more than 200,000 stars and searches for minute drops in brightness as the planets transit in front of each star.

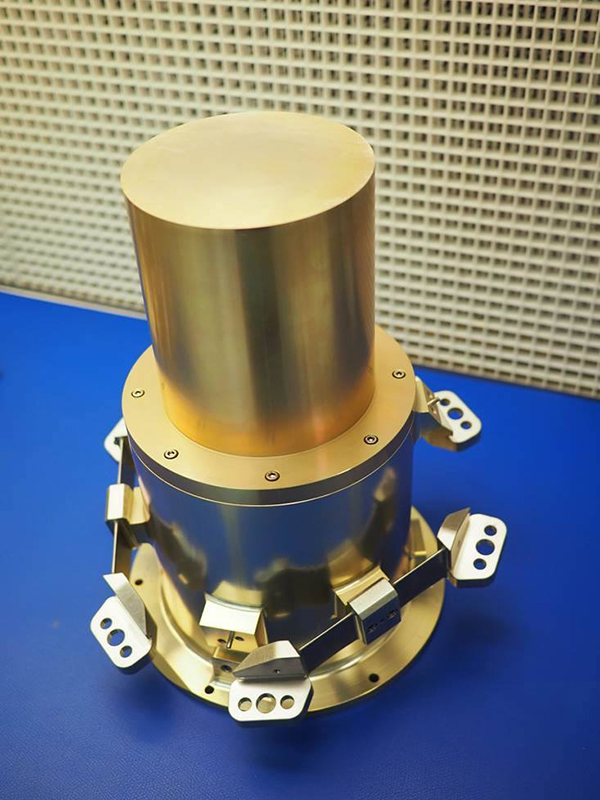

Making the mounting brackets required machining Invar, a nickel-iron alloy with a low thermal expansion coefficient, allowing it to meet the rigors of launch and enabling it to compensate for the extreme temperature swings of outer space. The mounting bracket has exceedingly tight tolerances. The central rib’s thickness is .050" +/- .001", perpendicularity between surfaces is held to .001" and the bracket’s two opposing surfaces must be in-line with each other to within .001".

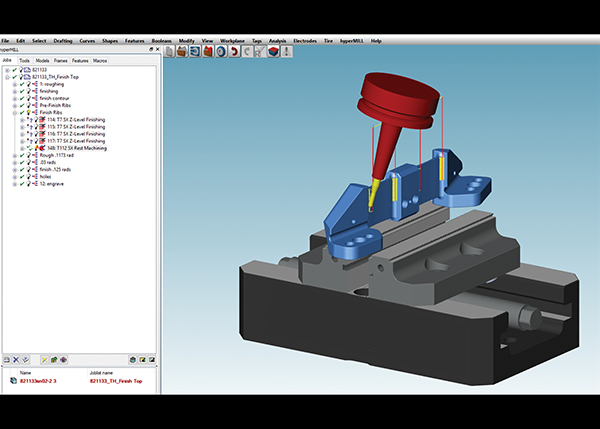

To cut Invar and achieve the required tolerances, Ramco used a hyperMILL generated 5-axis profile finish tool path. By doing this, an accurate finish across each part was achieved, keeping them within these very tight tolerances.

Mounting Brackets shown on camera-mount holder mock-up.

hyperMILL generated 5-axis profile finish tool path for camera-mount brackets.