hyperMILL 2017.1 means greater performance, more process reliability and increased flexibility.

- Significant auxiliary processing time savings can be achieved during mill turning with hyperMILL millTURN-Linking.

- Numerous new functions for 2.5D, 3D and 5axis milling increase efficiency.

These include 3D-optimised roughing and 5axis swarf cutting with a curve. - The hyperMILL MAXX Machining performance package has also been extended.

- And, hyperCAD-S once again features many new highlights.

![]() Download a hyperMILL Version 2017.1 brochure

Download a hyperMILL Version 2017.1 brochure

What’s new in hyperMILL 2017.1

General | Freely definable tool cutting edge

This extension allows freely definable tool geometries to be used for machining in selected 2D cycles. hyperMILL® uses the free geometries of the tool cutting edge for simulation and collision checking.

Suitable for the following 2D strategies:

- Contour milling on 3D models

- Playback milling

- Plunge milling

Benefit: Flexible tool definition, increased safety during collision checking, use of special tools.

hyperMILL MAXX Machining | High-performance cutting (HPC)

A new option allows the spindle speed to be adjusted in the plunge macro for roughing. Modifying the spindle speed and specifying a dwell time for the speed change ensures more toolfriendly machining. This option is available for all roughing jobs in the 2.5D, 3D and 5-axis area.

Benefit: Tool-friendly, greater process reliability.

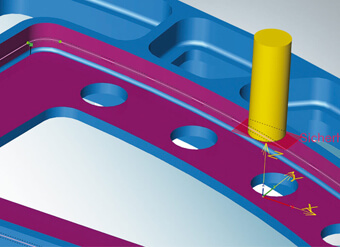

CAM – 2.5D strategies | 2D T-slot milling on 3D models

This is a new strategy for the efficient machining of T-slots. Various tool references and an optimised axial infeed allow T-slots to be machined safely. All toolpaths are checked for collisions and therefore provide maximum safety.

Benefit: Fast machining of T-slots, user-friendly.

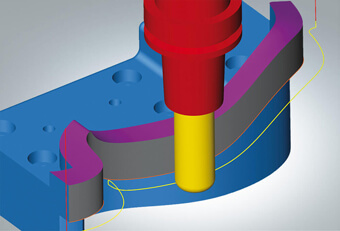

CAM – 3D strategies | 3D cutting edge machining

This is a new cycle for the optimised 3D machining of cutting edges. Roughing and finishing operations are generated via a 3D curve selection. The rest material machining is generated via the ‘Reference job’ option. Here, the rest material areas of the previous machining operation are also included in each case. Toolpath smoothing ensures a better milling result if the contours are of poor quality. This strategy guarantees efficient machining, particularly for cutting dies.

Benefit: Fast and easy programming of cutting edges.

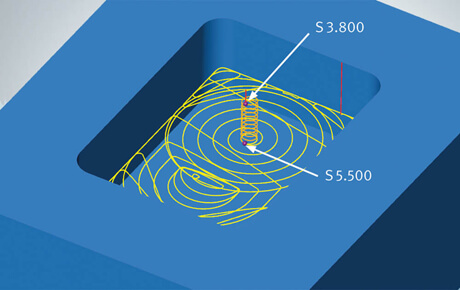

3D optimised roughing: adaptive pocket

With the help of this extension, adaptive pockets are fitted into the area to be roughed. As a result, high feedrate cutters can be used more efficiently and the linear machine movements allow higher feedrate values to be achieved than before. The machining can be executed as an adaptive pocket or as an adaptive pocket in combination with conventional roughing. Here, the toolpaths of the adaptive pocket and the remaining machining are optimally connected.

Benefit: Simple and fast programming, fast milling.

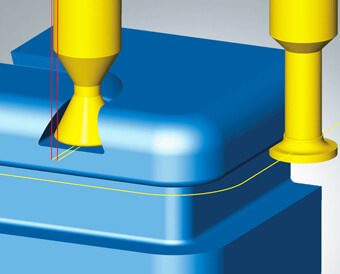

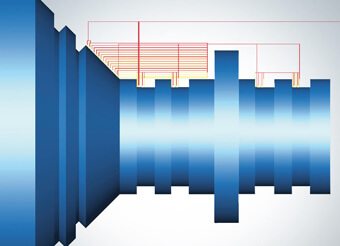

CAM – 5 axis strategies | 5-axis swarf cutting with a curve

Two new functions ensure greater user-friendliness. A perfect surface and an equally perfect curve are created automatically for swarf cutting based on selected geometries via a surface selection. Interior corners are filleted automatically. This ensures optimal machining.

Benefit: User-friendly, fast and easy programming.

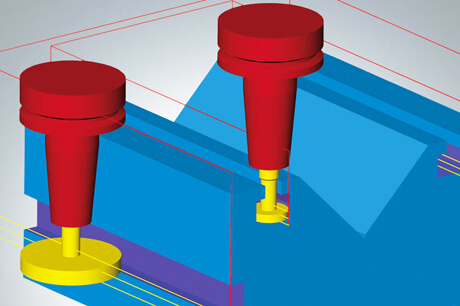

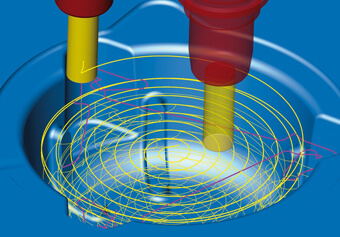

CAM mill turning | hyperMILL millTURN-Linking

hyperMILL millTURN-Linking allows multiple job steps, which can be machined with the same tool, to be combined intelligently into a single job step. This eliminates retraction movements between the individual operations and significantly reduces auxiliary processing times. All connecting paths are optimised with respect to the component and checked for collisions.

Benefit: Reduced auxiliary processing times.

Perfect fusion of virtual and real machining

Real machine collisions not only cause damage to machines; they also lead to production losses and associated time delays. This is why the actual machining situation, that is, the machine including controller and PLC, is mapped virtually and simulated based on the NC code in the hyperMILL VIRTUAL Machining Center. In addition, the innovative hyperMILL VIRTUAL Machining Connector provides in-depth, unique networking and synchronisation with the machine.

Reliable and comprehensive simulation: Often, machine movements are only simulated on the basis of internally used data. In other words, simulation takes place before the postprocessor run. In this type of CAM-based simulation, the postprocessor and simulation remain unconnected. With its hyperMILL VIRTUAL Machining Center, OPEN MIND has decided to go one major step further by ensuring that the simulation is based on the NC code after the postprocessor run.* Here, the virtual machine movements correspond exactly to the real machine movements. Only this machine simulation based on the NC code can guarantee reliable collision detection – even before starting on the machine.

*hyperMILL VIRTUAL Machining requires a hyperMILL Virtual Machining postprocessor.

Networking in real time – Machines are opening up as Smart Factory advances. With its hyperMILL VIRTUAL Machining Connector, OPEN MIND is for the first time offering a bidirectional exchange of data with the machine controller. This way, the CAM and machine world are networked in the best possible way and so-called ‘Connected Machining’ becomes a reality – an absolute highlight. Extensive advantages are opened up to companies on this new level of industrial digitalisation to secure long-term improvements in their processes and products.

Zero point alignment with the real machine

The machine zero points are aligned with those of the NC program. Clamping errors or incorrect positions are avoided.

Automatic tool comparison

Tool data from the NC program is automatically compared with the tool data of the machine. If this data does not match, an error message is output and the program run is halted.

NC block synchronisation

The NC block of the machine can be synchronised with the hyperMILL® VIRTUAL Machining Center; the machining position of the machine simulation after the synchronisation corresponds exactly to the real machine position.

NC program transfer

The NC program is loaded directly into the memory of the machine controller.